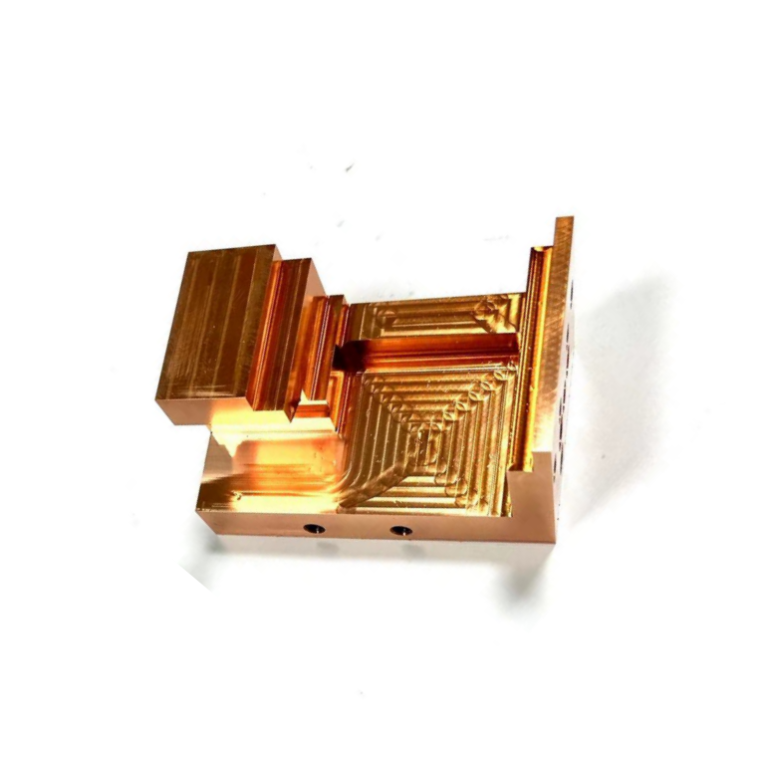

CNC Machining Brass and Copper Parts

In the modern CNC machining industry, CNC machining of brass and copper parts has always been popular. Copper is one of the easiest materials to machine in CNC machining. Brass is a copper alloy with zinc as the main additive element, presenting a beautiful yellow color. The proportions of zinc and copper can vary, creating different types of brass with varying properties. Brass has higher malleability than bronze and is one of the most widely used materials in the world.

In CNC machining, brass features low friction, excellent electrical conductivity, and a golden appearance. Brass is a metal alloy with good machinability and excellent electrical conductivity, making it ideal for applications that require low friction. It is widely used in industries such as machinery manufacturing (including gears, bearings, valves), electronics and electrical, aerospace, hardware products, musical instrument manufacturing, marine and shipbuilding, and automotive manufacturing.

CNC Machining for brass material parts

CNC Machining for brass material parts

360 brass is known as machinable brass, and is also commonly referred to as free-cutting brass or easy-to-machine brass. The machinability of 360 brass is the highest among all copper alloys. It offers excellent cutting performance, reducing tool wear during machining, and is suitable for various machining operations such as turning, milling, drilling, and tapping. It can be precisely machined into parts of various shapes and sizes to meet the needs of different applications. 360 brass is used to manufacture various components such as gears, locks, pipes, and trim parts. Additionally, 360 brass is widely used in electronic hardware and contacts, musical instruments, automatic screw machine parts, bolts, faucet seats, fluid connectors, and other fields.

| Brass | ||||

| Yield Strength (tensile) | Elongation at Break | Hardness | Density | Maximum Temp |

| 15,000 psi | 53% | Rockwell B35 | 0.307 Ibs / cu. in. | 1650°F |

CNC Machining for Bronze Materials Parts

932 bronze is a high-performance copper alloy, also known as CDA932 or C93200 bearing bronze. It has high strength and hardness, allowing it to withstand significant mechanical loads. Due to its content of tin, lead, and zinc, it offers excellent wear and corrosion resistance. It is most commonly used in bearings, bushings, and thrust washers.

| Bronze | ||||

| Yield Strength (tensile) | Elongation at Break | Hardness | Density | Maximum Temp |

| 18,000 psi | 10% | Rockwell B34 | 0.322 Ibs / cu. in. | 500°F |

CNC Machining for Copper Material Parts

The excellent thermal and electrical conductivity of 101 and 110 copper alloys makes them a natural choice for bus bars, wire connectors, and other electrical applications. 101 copper (also known as superconducting copper) is more conductive due to its high purity (99.99% copper) but is more cost-effective because 110 is easier to process.

110 Copper

The full name of 110 copper is C11000, which belongs to the category of electrolytic tough copper (ECP). It has good electrical conductivity, thermal conductivity, corrosion resistance, and excellent machinability.

C11000 copper contains approximately 99.9% copper and is low in oxygen content. Due to the low oxygen content, it exhibits excellent electrical conductivity, superior ductility and toughness, good corrosion resistance, and excellent weldability.

| Tensile Strength, Yield (MPa) | Coefficient of Thermal Expansion: | Density (p) | Melting Point | Elongation (ε) at break |

| 32,000 psi | 0.0000098°F (68-572°F) | 0.321-.323 lbs/cu in | 1949°F | 55% (in 2″) |

C10100 Copper

C10100 copper is oxygen-free copper with a purity of over 99.99%, containing extremely low levels of impurities. It has excellent electrical and thermal conductivity, good machinability, and corrosion resistance. It can be applied in high-end manufacturing industries: in the production of precision instruments, meters, sensors, and other devices, it serves as a key material for conductive and thermal components, helping to improve the accuracy and stability of equipment.

| Tensile Strength,Yield (MPa) | Hardness VPN | Density(p) | Melting Point | Elongation (ε) at break |

| 200-400 MPa | 40-120 | 8.92 g/cm3 | 1083°C | 5-50% |

JUNYU– One of The Most Professional CNC Machining Brass Parts Manufacturer

JUNYU is a manufacturer specializing in CNC machining of brass and copper parts. With over 10 years of CNC machining experience, JUNYU has the most professional technical team capable of providing design suggestions and handling various issues in CNC machining.

We are equipped with over 100 of the latest CNC machining centers, and JUNYU offers a full range of precision CNC machining services: CNC milling, CNC turning, CNC drilling, CNC wire cutting, precision EDM, and CNC grinding. Our CNC machining capabilities for brass parts enable us to deliver high-quality brass components with high precision and accuracy, ensuring consistency with customer designs or drawing specifications.

What are the advantages of CNC machined copper or brass parts?

1.Excellent Electrical and Thermal Conductivity: Copper has outstanding electrical and thermal conductivity, making it a common material in electrical and electronic products, such as wires, cables, connectors, etc.

2.Good Corrosion Resistance: Copper offers strong corrosion resistance in most environments, particularly against seawater, salt spray, and acidic/alkaline conditions. It is widely used in marine, chemical, and other industries.

3.High Strength and Good Malleability: Copper not only has high strength but also possesses good plasticity during cold processing, allowing for the production of precision parts suitable for complex machining requirements.

4.Ease of Machining: Copper materials are easy to machine and are suitable for various machining processes, including turning, milling, drilling, etc. They can be easily shaped into complex forms and fine dimensions.

5.Good Weldability: Copper has excellent welding properties, allowing for efficient and reliable welding, making it ideal for assembling various mechanical and electronic devices.

6.High-Temperature Resistance: Copper retains its stability at high temperatures, making it suitable for parts used in high-temperature environments, such as heat exchangers and radiators.

7.Friction and Wear Resistance: Copper has good anti-friction and wear-resistant properties, commonly used in parts subjected to friction and wear, such as bearings and gears.

8.Aesthetic Appeal: Copper has a unique metallic luster and color, making it ideal for applications where appearance is important, such as decorative parts and art pieces.

9.Environmental Friendliness: Copper is a recyclable material that meets environmental standards and is widely used in green technologies and sustainable development fields.