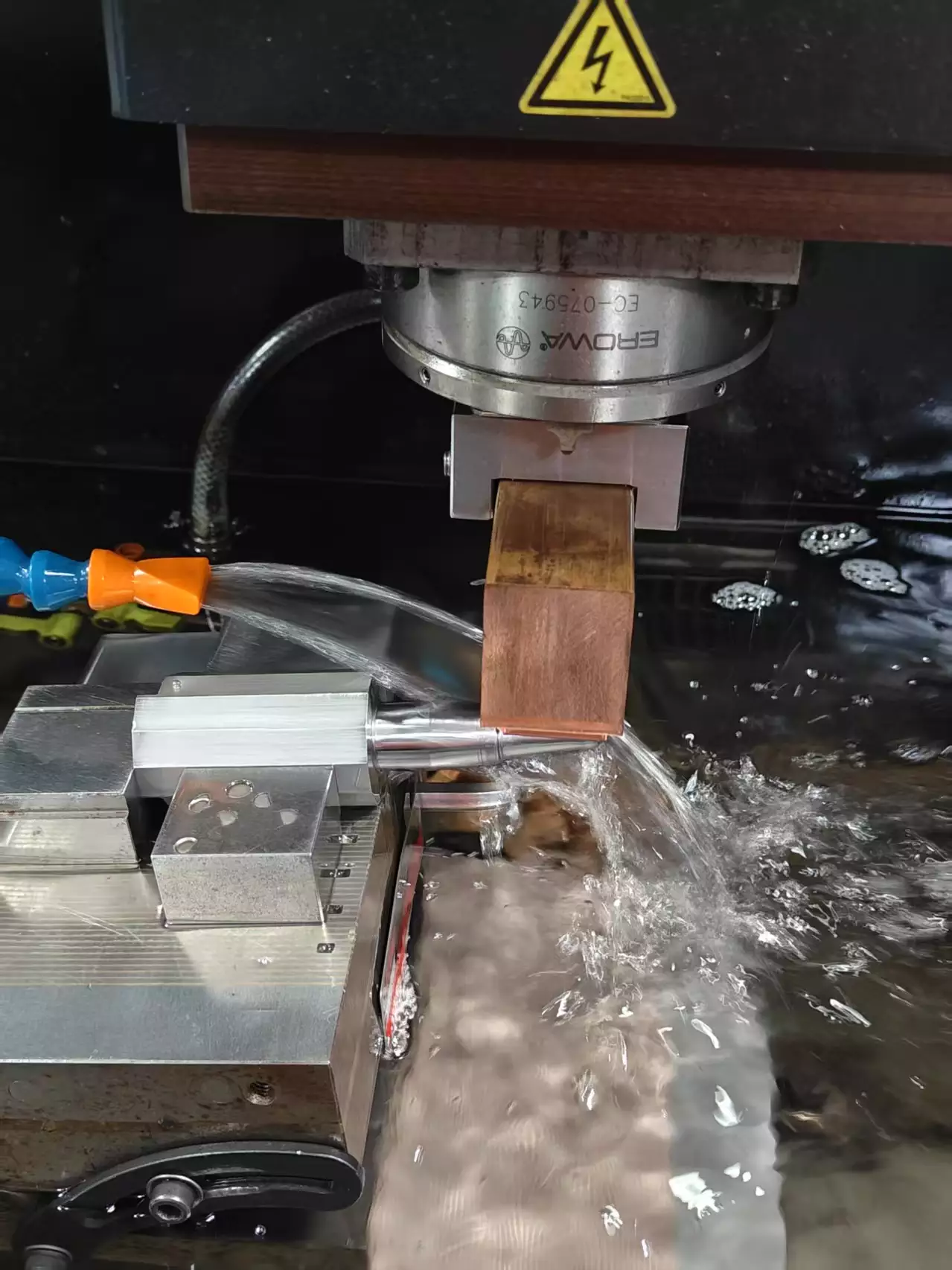

Precision Electrical Discharge Machining (Precision EDM)

Precision Electrical Discharge Machining (Precision EDM), also known as Electrical Discharge Machining (EDM), is a process in which a pulsed discharge phenomenon occurs between an electrode and the workpiece, generating instantaneous high temperatures (over 10,000°C) in an insulating working fluid. This causes the metal material to locally melt or vaporize. Through the cumulative effect of countless tiny discharges, material from the surface of the workpiece is gradually removed, forming the desired shape. Essentially, precision EDM is a synergistic process of electrical, thermal, mechanical, and material removal.

The advantages of EDM machining.

EDM (Electrical Discharge Machining) is a machining method that uses pulse discharge energy to remove material. Its advantages are primarily reflected in the following aspects:

1.High Precision

The precision can reach ±0.002mm, and the surface roughness is high (Ra < 0.2μm), making it suitable for precision part processing.

2.Suitable for Hard and Brittle Materials

EDM is particularly suited for processing materials with high hardness or brittleness, such as hardened steel, titanium alloys, metal ceramics, and carbides. These materials are often difficult to process with traditional cutting methods, but EDM can handle them with ease.

3.Complex Shape Machining Capability

EDM can process very complex cavities, narrow gaps, deep holes, and fine structures (such as precision patterns for molds or small holes for turbine blades). It performs excellently in mold manufacturing, deep hole processing, and fine contours, making it ideal for processing complex geometries and small details that conventional machining methods cannot accomplish.

4.Non-Contact Machining

EDM removes material through the electrical discharge between the electrode and the workpiece, so there is no physical cutting force involved. This makes it particularly suitable for fragile, deformable, or irregularly shaped workpieces, avoiding stress or deformation caused by mechanical processing.

5.High Automation

With the integration of CNC systems, EDM can be program-controlled, making it suitable for batch production and complex trajectory machining while reducing manual intervention.

6.High Surface Quality

EDM can leave a smooth surface on the workpiece. In particular, pulse EDM technology can further enhance surface quality. Although some cases may require post-processing for surface treatment, compared to other traditional machining methods, EDM generally provides better surface finish.

7.Suitable for Micro Machining

EDM has unique advantages in the machining of micro parts. Micro EDM can precisely process tiny apertures, micro structures, and fine details, making it suitable for micro components in fields such as electronics, medical devices, and aerospace.

8.Flexibility

EDM does not rely on traditional tool wear, but rather the selection of the electrode to change the shape and size. This allows for easy adaptation to a wide range of parts and material processing needs, especially for complex and customized part manufacturing.

9.Smaller Heat-Affected Zone

Because EDM uses brief, high-temperature discharges rather than continuous heating, the discharge time is extremely short (in microseconds). The heat is concentrated in a localized area, resulting in minimal overall thermal deformation of the workpiece, making it suitable for thin-walled, easily deformable parts.

10.Suitable for Micro and Deep Hole Machining

EDM is particularly suitable for micro hole and deep hole machining. Compared to other methods, EDM can efficiently process hard-to-achieve deep holes and tiny apertures without clogging or debris accumulation.

The Secrets of Precision Control in Electrical Discharge Machining (EDM)

Precision Electrical Discharge Machining (EDM) achieves high precision through a combination of several critical factors. These factors work together to control and refine the process, ensuring exceptional accuracy. Below are the key “secrets” to precision control in EDM:

1. Precise Control of Current and Pulse Width

In EDM, the intensity of the current and pulse width directly affect material removal rate and precision. Smaller pulse widths allow for finer material removal, which enhances machining accuracy.

The control of current helps prevent excessive discharge energy, thus reducing surface roughness and electrode wear.

2. Role of Dielectric Fluid

EDM is performed in an insulating dielectric fluid that not only cools the discharge area but also removes debris and gas bubbles generated during machining. This helps prevent interference with machining precision.

The temperature, flow rate, and cleanliness of the dielectric fluid must be kept constant to maintain consistent machining accuracy and surface quality.

3. Selection of Electrode Shape and Material

The material and shape of the electrode are crucial for machining precision. Common electrode materials include copper, graphite, and copper alloys. The surface finish of the electrode also directly impacts the final result.

The shape of the electrode should match the workpiece shape to ensure that the final part is formed to the exact specifications.

4. Servo Control System

Precision EDM utilizes high-precision servo control systems to dynamically adjust the gap between the electrode and workpiece during machining. This is essential for maintaining precision.

The servo system can automatically adjust the electrode position to compensate for electrode wear, ensuring machining accuracy throughout the process.

5. Temperature Control

High temperatures generated during EDM, particularly the instantaneous heat during discharge, can cause dimensional and surface changes in the workpiece. Precise temperature control systems help prevent thermal deformation of the workpiece.

Using appropriate cooling systems, such as liquid and gas cooling, minimizes temperature fluctuations and ensures high-precision machining.

6. Precise Planning of Machining Path

Careful planning of the machining path is crucial in precision EDM. By calculating and planning the discharge sequence and step sizes, it prevents over-machining of localized areas or uneven material removal, thus improving overall accuracy.

7. High-Precision Equipment

Precision EDM requires machines with extremely high precision. Modern EDM machines are equipped with advanced positioning systems and automated control technologies that ensure precise control over electrode movement and the discharge process during machining.

8. Real-Time Monitoring and Feedback Control Systems

Advanced EDM machines are equipped with real-time monitoring systems that collect data from the machining process, such as current, voltage, and gap changes. This data is used to adjust the machining process to ensure the workpiece remains in an accurate machining state.

Feedback control systems automatically adjust the machining parameters based on real-time data, further improving precision.

9. Experience and Process Optimization

Precision control in EDM also relies heavily on the experience of the operator. Through multiple trials and parameter optimization, the operator can adjust the process to achieve the best precision for a specific workpiece.

Continuous experience accumulation and data analysis allow for process improvements, enhancing machining stability and precision.

Conclusion:

Precision control in Electrical Discharge Machining is a multi-faceted process, involving the regulation of current and pulse width, control of dielectric fluid, electrode selection and wear compensation, servo systems, temperature control, and machining path planning. Through these precise control methods, EDM can deliver exceptional performance in high-precision manufacturing, especially for complex parts, fine holes, and deep cavities.

Types of Spark Discharge Machining (EDM)

1.EDM Forming

2.Sinker EDM (Ram EDM)

3.Wire EDM

4.EDM Drilling

5.Micro EDM

6.Pulsed EDM

7.High-speed EDM

Application areas of parts processed by EDM.

EDM (Electrical Discharge Machining), with its non-contact, high-precision, and ability to machine hard and brittle materials, plays a critical role in various high-end manufacturing sectors. Below are its core application areas and typical scenarios:

1.Mold Manufacturing:

Applications include injection molding molds, die-casting molds, stamping molds, mold cores, mold cavities, and complex cooling channels.

2.Aerospace:

Applications include engine parts, spacecraft structural components, ceramic matrix composites (CMC), tungsten alloy nozzle parts.

3.Electronics and Semiconductor Manufacturing:

Applications include semiconductor packaging molds, micro connectors, precision switches, and precision processing of electronic components.

4.Medical Devices and Biomanufacturing:

Applications include implantable devices, medical mold tools, surgical instruments, dental equipment, implants, precision needles, micro components, etc.

5.Automotive and New Energy Sectors:

Applications include automotive components, lithium battery electrode molds, hydrogen fuel cell plates.

6.Optics and Precision Instruments:

Applications include lens molds, sensor housings, gyroscope frames, and prism processing.

7.Other High-end Manufacturing Sectors:

Applications include jewelry, tool manufacturing.

8.Special Parts Manufacturing:

Applications include high-precision small holes, high-precision micro parts, complex internal cavities and deep cavity components, micro gears, etc.

Mold Manufacturing

Medical Devices and Biomanufacturing

Aerospace

Electronics and Semiconductor Manufacturing

Other High-end Manufacturing Sectors

Special Parts Manufacturing

Automotive and New Energy Sectors

Optics and Precision Instruments

Challenges and Limitations of EDM Machining

1.Low Processing Efficiency and Slow Speed

Compared to traditional cutting methods, EDM relies on the principle of electro-erosion, which results in a lower material removal rate. Therefore, its efficiency is lower in large-scale production. The process takes longer, especially when machining complex shapes and large workpieces.

2.High Processing Costs

Electrode Wear and Replacement: Electrodes made of materials such as copper and graphite continuously wear down during EDM machining. The wear of the electrodes affects the accuracy of the workpiece, requiring frequent calibration or replacement, which increases processing costs and maintenance work. Furthermore, complex parts may require multiple sets of electrodes or frequent corrections, further increasing consumable costs.

EDM Equipment and Maintenance Costs: CNC-EDM equipment is expensive and requires specialized EDM working fluids and cooling systems, contributing to high maintenance costs.

Waste Fluid Treatment Costs: After prolonged use, the working fluid accumulates metal debris and carbides, which must be professionally treated to meet environmental standards, thus increasing costs.

3.Material Adaptability Limitations

Limited to Conductive Materials: EDM can only process conductive materials, meaning non-conductive materials, such as plastics, glass, and pure ceramics, cannot be processed directly. They must undergo additional treatments (e.g., coating) to become conductive for EDM processing.

Low Efficiency with High Melting Point Materials: For metals with extremely high melting points, such as tungsten and molybdenum, the discharge energy needs to be significantly increased, which leads to greater electrode wear and further reduces processing efficiency.

4.Surface Roughness

Although EDM can provide a relatively smooth surface, the high temperatures generated during discharge may cause micro-cracks or a hardened layer on the workpiece surface, forming a heat-affected zone. In high-precision fields such as aerospace, post-processing heat treatment is required to eliminate these effects.

5.Limitations on Processing Depth and Complex Structure

Depth-to-Diameter Ratio Limitation: When processing deep holes or narrow slots, the electrode’s rigidity may not be sufficient, leading to deflection, and chip removal can be difficult, which may cause unstable discharges.

Risk of Thin-Walled Part Deformation: Although EDM does not involve cutting forces, the prolonged discharge heat effect may deform thin-walled parts. Strict control of process parameters is required.

6.Need for Specialized Operational Skills

EDM machining requires operators to have high levels of skill and experience, especially in selecting the appropriate electrodes, adjusting discharge parameters, and dealing with electrode wear. Inexperienced operators may not be able to fully utilize the potential of EDM equipment.

7.High Environmental Requirements

EDM requires a stable power supply, clean dielectric fluid, and an appropriate temperature environment, or else machining precision and surface quality may be affected. Additionally, the process generates sparks and high temperatures, necessitating good safety measures and a suitable working environment.

Summary:

While EDM offers many advantages, such as high precision and the ability to process complex shapes and hard, brittle materials, it also faces challenges such as slow processing speed, electrode wear, and high costs. To maximize its benefits for specific applications, selecting suitable materials, optimizing process parameters, maintaining equipment, and improving operational skills are key factors in overcoming these limitations.

The process parameters of EDM machining.

The EDM (Electrical Discharge Machining) process parameters are key to controlling machining quality and efficiency. Correct setting of these parameters can optimize machining results. Below are some common EDM process parameters:

1.Pulse Duration

Unit: Microseconds (μs)

Function: Pulse duration is the time for each discharge, directly determining the discharge energy. A larger pulse duration increases material removal rate, but may lead to poor surface quality and higher electrode wear; a smaller pulse duration helps improve precision and surface quality but reduces efficiency.

2.Pulse Interval

Unit: Microseconds (μs)

Function: Pulse interval is the time between two discharge pulses. A smaller pulse interval results in a higher discharge frequency, improving machining efficiency, but causes poorer electrode heat dissipation and higher wear; a larger pulse interval improves electrode heat dissipation and reduces wear but decreases efficiency.

3.Peak Current

Unit: Amperes (A)

Function: Peak current determines the energy of each discharge. The higher the current, the higher the material removal rate, but surface roughness increases, and electrode wear rises; lower currents improve precision but reduce efficiency.

4.Discharge Voltage

Unit: Volts (V)

Function: Discharge voltage influences the discharge gap between the electrode and the workpiece. Higher voltage increases the discharge gap, which is suitable for rough machining and better chip removal; lower voltage enhances precision and surface quality but makes chip removal more difficult, which is ideal for finishing operations.

5.Electrode Material and Wear

Material Selection:

Copper: Suitable for precision machining, with lower wear and high accuracy, ideal for medium and small parts or finishing operations.

Graphite: Resistant to high temperatures and low wear, suitable for high current rough machining or large parts.

Electrode Wear Control: Higher current and pulse duration lead to greater electrode wear, so optimal parameter settings are necessary to extend the life of electrodes.

6.Dielectric Fluid

Type: Specialized EDM dielectric fluid

Function: Cooling, chip removal, and insulation. If the fluid’s purity is insufficient or its flow rate is too low, it can lead to poor chip removal, short circuits, or degraded surface quality.

7.Feed Rate

Unit: Millimeters per minute (mm/min)

Function: The feed rate of the electrode determines the rate at which the gap between the electrode and the workpiece changes. If the feed rate is too fast, it may cause short circuits; if too slow, the efficiency decreases.

8.Discharge Energy

Unit: Determined by current and pulse duration

Function: Discharge energy is the primary factor determining the energy of each discharge. Higher discharge energy helps increase material removal rate but may negatively affect surface quality. Lower discharge energy improves surface quality but lowers removal rate.

9.Spark Gap

Unit: Millimeters (mm)

Function: The spark gap between the electrode and the workpiece determines the stability of the discharge and the material removal efficiency. If the gap is too large, the discharge may become unstable, affecting machining precision; if too small, it may cause short circuits or overheating of the electrode and workpiece.

Comparison Table of Characteristics Between Traditional Electrical Discharge Machining and Precision Electrical Discharge Machining

| Characteristics | Precision EDM | Traditional EDM |

| Machining Accuracy | High precision ±0.002 – 0.01mm, even up to ±0.001mm | Usually ±0.01 – ±0.05mm |

| Surface Roughness (Ra) | 0.1 – 0.8μm; mirror – finish machining can reach below 0.08渭m | 1.6 – 3.2μm |

| Electrode Wear Rate | Relatively low; intelligent pulse control reduces wear and prolongs electrode service life | Relatively high; electrodes need to be replaced frequently |

| Machining Efficiency | Relatively low efficiency; precise parameter control is required to ensure accuracy | High efficiency in rough machining, suitable for large – area material removal |

| Equipment Control System | High – precision CNC system with feedback control and intelligent adjustment | Simple control system; much manual adjustment needed, low automation level |

| Pulse Power Technology | Precisely controls pulse width, current, and pulse interval, suitable for high – precision machining | Relatively simple pulse control, suitable for rough machining |

| Working Fluid Treatment | Working fluid for EDM machines with a high – precision filtration system | Working fluid for EDM machines |

| Application Scenarios | Precision molds (e.g., semiconductor packaging molds, optical molds), precision parts for aerospace, medical devices, etc. | Rough machining of ordinary molds, blank forming of parts |

| Equipment Cost | Relatively high; imported equipment can cost several million yuan | Relatively low, suitable for rough machining and large – scale production |

FAQ

What is the machining precision of electrical discharge machining (EDM)?

The precision of electrical discharge machining (EDM) is typically at the micrometer level, and it can generally be controlled within ±0.001mm to ±0.005mm.

For example, Mitsubishi’s precision EDM machine can achieve a machining accuracy of ±0.001mm. Sodick’s high-speed EDM machines have a spacing accuracy of ±0.002mm and a depth accuracy of ±0.001mm. On the other hand, some standard EDM machines may have slightly lower precision, with accuracy ranging from ±0.01mm to ±0.05mm.

How is the cost of EDM machining calculated?

The simplified cost calculation formula for EDM machining:

Total Cost ≈ (Equipment Energy Cost + Consumables Cost + Labor Hourly Cost) × Machining Time + Other Miscellaneous Costs

Can sample machining be provided?

Yes, we can provide sample machining services. Customers can provide the drawings along with their requirements, and we will process them according to your needs, ensuring machining accuracy and quality.

Try JUNYU Out Now In Just A Few Steps

Upload your 2D/3D files

Simply upload your project files—our engineering team will review them and deliver a customized solution promptly.

Your Order Get Started

As long as we receive your confirmation, we will start your project immediately.

Receive Your Order

Your custom machined parts will be delivered right to your doorstep.

Ready to place your order? Fill out the form below to get in touch with us!