CNC Machining Service

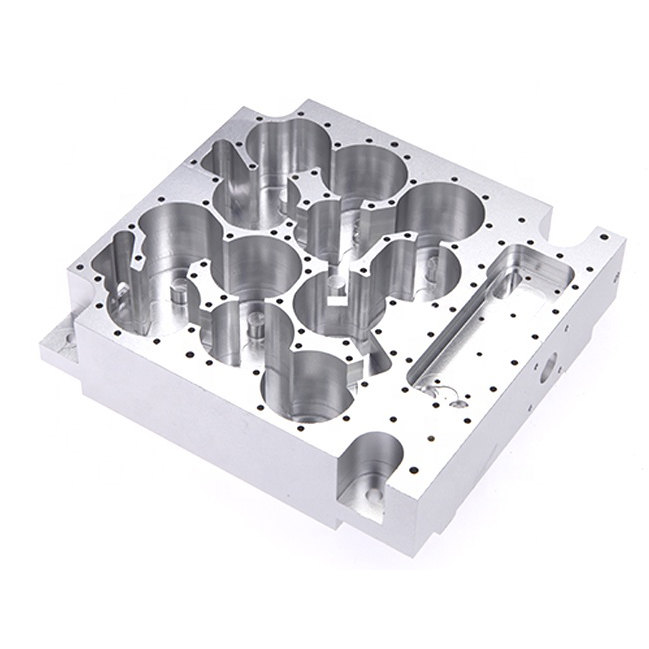

JUNYU offers a dependable one-stop CNC machining solution, delivering rapid prototyping and end-use part production across a wide range of materials. We support precision machining services for parts of all sizes—small, medium, and large—ensuring flexibilityand consistency throughout the manufacturing process.

Our CNC Machining Capabilities

As one of the leading precision CNC machining service providers in China, JUNYU offers comprehensive manufacturing capabilities to meet all your CNC part requirements—from rapid prototyping and precision component and tooling fabrication to end-use part production.

High-precision parts manufactured and delivered within 24 hours

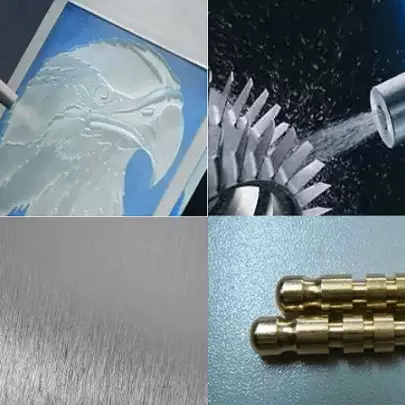

CNC milling, CNC turning, wire EDM, EDM, etc.

Standard dimensional tolerance of ±0.005mm

We have passed ISO 9001:2008, and TS16949 quality system certification in 2015

The machined parts will be shipped to you in a short time

Rapid prototyping across a wide range of materials, with multiple mold types available to suit different production needs.

CNC Machining Processes

CNC Milling Service

CNC milling utilizes advanced 3-axis and 5-axis indexed machining technology to rapidly process more than 30 types of engineering-grade thermoplastics and metals into complex structures and high-precision components.

As a subtractive manufacturing process, milling removes excess material from solid stock by cutting and drilling the workpiece using precision tools. This technique offers both high speed and high accuracy, making CNC milling highly efficient for producing precision parts.

CNC Turning Service

CNC Turning uses a lathe to machine precise end-use parts with cylindrical geometries. The process removes excess material from solid stock by rotating the workpiece against stationary cutting tools.

CNC turning is highly suitable for manufacturing cylindrical components and offers a cost-effective way to produce high-quality parts.

CNC Milling and Turning:A multi-process composite machining technique that enables high-efficiency and high-precision manufacturing of complex curved surfaces and contoured parts through the simultaneous rotation of the tool and workpiece, combined with coordinated multi-task operations.

CNC Drilling:This is a machining technique adopted by JUNYU, offering greater flexibility and operational capability to meet a wide range of complex CNC machining requirements. Whether for small-batch prototyping or large-scale production, this process enables efficient drilling of holes with diameters exceeding 7 cm, and is suitable for metals, alloys, and various polymer materials.

Materials for CNC Machining Parts

CNC Machining Steel Parts

Steel is one of the most widely used materials in metalworking. With its high strength, excellent machinability, and outstanding cost-performance ratio, it is extensively applied across various industries—from precision component manufacturing to structural engineering.

At Junyu, we offer CNC machining services for over 100 types of steel, delivering high-quality, customized precision machining solutions to meet the diverse needs of our clients, from prototype development to full-scale production.

Alloy Steel/ Carbon steel / 4140 / 4340 / Q235 / Q345B / 20# / 45#, etc

CNC Machining Aluminum Parts

Aluminum alloy precision parts are highly favored for their lightweight and refined appearance. CNC machining can perfectly showcase the excellent physical properties and fine processing effects of aluminum materials. As a result, CNC machining has become the preferred process for aluminum prototyping and small batch production.

At JUNYU, we can provide CNC machining of most aluminum. Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380, etc.

CNC Machining Stainless Steel Parts

Stainless steel is one of the most commonly used materials. In the machinery industry, CNC machining is the mainstream method for stainless steel processing. The advantages of CNC-machined stainless steel parts lie in ensuring precision, durability, and performance, making them the ideal choice for precision manufacturing, industrial applications, and high-demand products.

At JUNYU, we offer CNC machining services for more than 10 types of stainless steel.

Including SS201, SS301, SS303, SS304, SS316, SS416, etc.

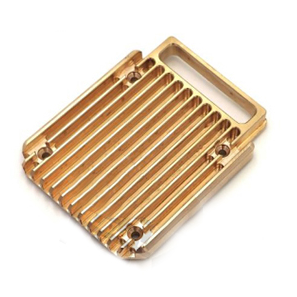

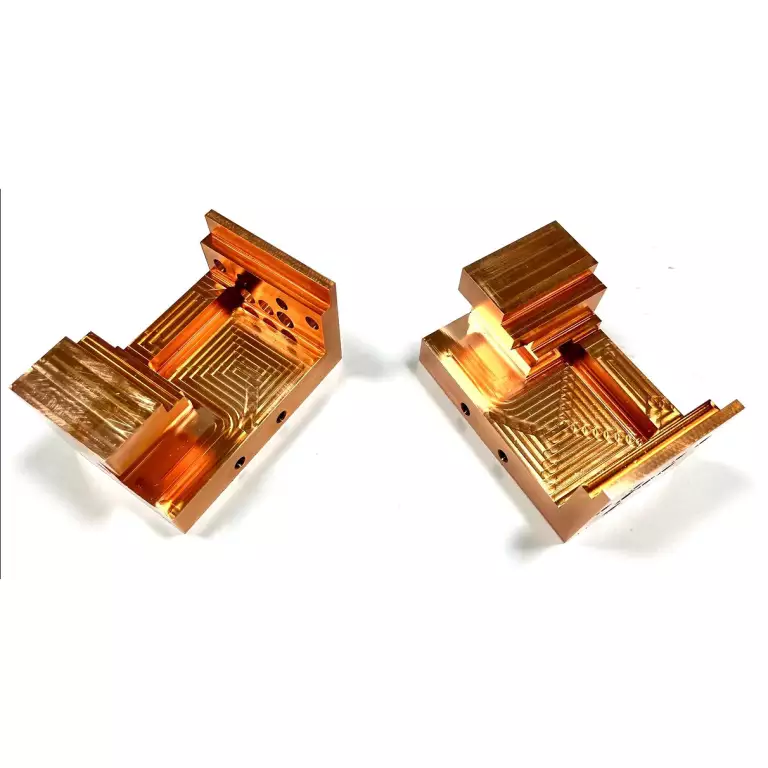

CNC Machining Brass/Copper Parts

Brass parts manufactured through CNC machining combine high precision, the ability to process complex shapes, and excellent physical properties, making them suitable for various industries, including electronics, automotive, aerospace, construction, and water treatment. The advantages in machining accuracy, surface quality, material properties, and production efficiency make it an ideal choice for producing precision and high-demand parts. JUNYU offers CNC machining services for most types of brass/copper available in the market. Using CNC turning, CNC milling, and other processes, we can transform your parts or products into exactly what you envision.

Brass: HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90, etc.

Copper: C11000 / C12000 / C12000 / C360, etc.

CNC Machining Titanium Parts

Titanium materials are materials with certain shapes, sizes, and performances made of titanium ingots and titanium alloy metals through certain pressure processing, and are also called titanium processed materials. CNC machining is a good choice for machining titanium material into titanium parts, which can reveal the details of titanium parts.

Our titanium machining capabilities include Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc.

CNC Machining Plastic Parts

CNC machining plastic parts offers several advantages over other processing methods, including high precision, the ability to process complex shapes, strong material adaptability, and quick adjustments. It is particularly suited for small batch production, rapid prototyping, and complex designs. Its efficiency, reliability, and flexibility make CNC machining the ideal choice for plastic part manufacturing, widely used in industries such as electronics, automotive, and medical.

At JUNYU, we transform plastics into parts or products through various methods, including CNC machining, CNC turning, CNC milling, and more.

Our CNC machining capabilities cover a wide range of materials, including PVC, PP, PS, and more.

Other Materials for CNC Machining

In addition to the above conventional materials, we also provide CNC machining services for other materials.

Inconel, Invar, Magnesium, etc.

Surface Finishes For CNC Machining

| As Machined | The surface is left untreated, retaining visible tool marks from the machining process. |

| Sandblasting | Used for cleaning, roughening, and enhancing the appearance of workpiece surfaces. It also improves surface adhesion and lubrication retention. This process is widely applied in metalworking, casting cleanup, and surface pretreatment operations. |

| Shotblasting | A widely used surface treatment process, suitable for roughening surfaces, deburring, removing oxide layers, enhancing texture, and improving the structural strength of materials |

| Wire Drawing | A surface treatment that gives the metal a directional, matte metallic texture through processing, resulting in a non-mirror finish. |

| Passivation | This removes surface contamination, increases corrosion resistance, reduces the risk of product contamination, and allows you to extend system maintenance intervals. |

| Logos printing | Customized logos, symbols, and text can be added to both prototypes and production parts using various methods. We offer services such as laser marking and silkscreen printing to meet diverse branding and functional requirements. |

| Anodizing | is an electrochemical surface treatment process commonly used on aluminum and its alloys. It is designed to enhance the material’s corrosion and wear resistance while also improving its aesthetic appearance. |

| Chrome Plating | It is a common metal surface treatment process that involves electroplating a layer of chromium (Cr) onto the surface of a workpiece. This technique significantly enhances the corrosion resistance of the part, increases surface hardness and wear resistance, improves surface finish, and effectively reduces the coefficient of friction, thereby extending the service life of the component and improving overall performance. |

| Zinc Plating | Mirror-like protection for aesthetics, anti-rust and other functions |

CNC Machining Products

We offer rapid prototyping and low volume production for clients in a broad range of industries. By harnessing advanced CNC technologies—including CNC milling, CNC turning, precision wire cut EDM, and high accuracy sinker EDM—we swiftly transform your ideas into high quality, ready to use parts

Our CNC machining capabilities enable the production of precision parts and custom components for clients in the aerospace, automotive and new energy vehicle, defense and military, medical device, electronics and semiconductor, industrial automation, machinery, consumer electronics and premium home appliance, marine engineering and shipbuilding, oil and gas, and robotics sectors.

Tolerances For CNC Machining

| Process | Tolerance(mm) |

| CNC Milling | ±0.005(metal) / ±0.05(plastic) |

| CNC Turning | ±0.005(metal) / ±0.05(plastic) |

| CNC Grinding | ±0.005(metal) / ±0.05(plastic) |

| The Best Surface Finishing | Ra0.1 |

Our standard dimensional tolerance for CNC-machined parts is ±0.005 mm (0.0002 in). Since turning, milling, and 5-axis equipment cannot always maintain this ultra-tight tolerance across every geometric feature, please specify any stricter requirements on your drawings or inform us before placing an order; we will then formulate the optimal manufacturing plan.

Machining thin-wall or sheet-metal parts may require dedicated fixtures. In such cases, our engineering and process teams will collaborate closely with you to design reliable, high-efficiency fixturing and machining solutions.

Size Limitation For CNC Machining

| CNC Milling | CNC Turning | |

| Max Diameter | 3500mm (138in) | 2500mm (99in) |

| Min Diameter | 0.1mm (0.003in) | 0.1mm (0.003in) |

Although our CNC machines can produce parts with intricate geometries and a wide range of sizes, they are still subject to certain dimensional constraints. To support design-phase evaluation, we have prepared a CNC machining size-limit table for your reference; it is essential that designers and engineers review these limits early in the design process. If your component exceeds the dimensions listed, please forward the drawings to us. We will assess feasibility and provide a tailored machining solution and quotation.

Lowest CNC Service Price

4 Key Advantages Behind Our Competitive Pricing

1. Advanced and Efficient Machining Equipment

We are equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers. High-speed, high-precision equipment significantly improves machining efficiency, shortens production cycles, and effectively reduces the unit cost.

2. Refined and Optimized Production Processes

With years of industry experience, we continuously optimize our production processes, minimizing material waste and setup time, enhancing overall operational efficiency, and reducing manufacturing costs.

3. Professional Engineering and Technical Team

Our engineers develop optimal machining strategies based on project requirements, selecting the most suitable tools and planning efficient machining paths to improve productivity, reduce errors, and control costs at the source.

4. Stable and Reliable Supply Chain System

We maintain long-term partnerships with premium material suppliers and logistics providers, ensuring low-cost procurement of high-quality raw materials and efficient delivery, further reducing overall production costs.

If you are looking for a low CNC service price, please do not hesitate to get a quote!

Why Choose JUNYU For CNC Machining?

We machine each part with exacting precision to your design and, when necessary, offer targeted design optimization suggestions to streamline manufacturing and reduce costs. For both metal and plastic components, we provide a wide array of surface finish options, and every product is produced to stringent dimensional tolerances to ensure superior quality and consistency.

Leveraging an experienced technical team and stringent quality management, we guarantee superior production efficiency and product quality. Junyu can deliver high-precision custom parts in as little as one day and provides 24 hour online support to meet your needs at any time.

Our CNC machined parts generally adhere to the DIN 2768 1 fine and medium tolerance classes; the exact tolerances achievable vary with each part’s geometry. Throughout the project, our engineers will discuss every component with you to ensure the optimal and most consistent machining accuracy for each piece.

Choose from an extensive catalogue of 100 + certified metals and plastics—our CNC machining service delivers the material flexibility your project demands.

We accommodate order quantities from a single piece up to large volume runs and work with a full range of metal and plastic materials. Our capabilities span both simple mechanical parts and the high precision manufacture of complex CNC components.

Our components are shipped worldwide, reaching customers in Europe, the United States, Australia, South America, the Middle East, and Southeast Asia.

JUNYU features a full-spectrum professional team—from sales consultants to senior engineers—delivering bespoke, top tier CNC machining solutions at highly competitive prices. We place our customers at the heart of everything we do and are committed to building long term, trust based partnerships with our clients. We look forward to collaborating with innovative enterprises to forge a prosperous, mutually beneficial future together.

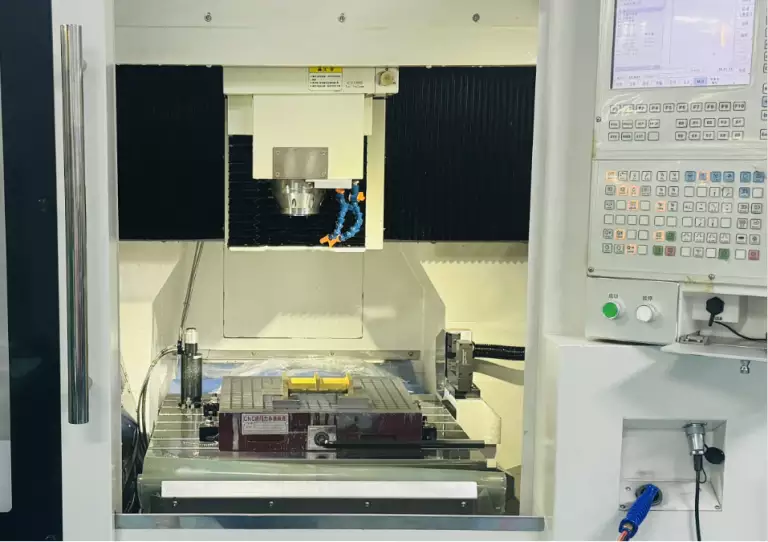

Our CNC Machining Center

Our CNC machining center is equipped with over 70 advanced devices, including 3-axis, 4-axis, and 5-axis CNC machines, which are capable of manufacturing parts that meet most of our customers’ requirements. In addition to the CNC machining centers, we also possess a number of high-end equipment such as precision grinding machines and precision wire cutting machines.

Our Partners

Overview of CNC Machining

What’s CNC machining?

Computer Numerical Control (CNC) machining is a precision subtractive manufacturing process in which machine tools are controlled by computer programs. In this process, the computer driven machines remove excess material from solid blocks of metal, plastic, composites, and other materials to achieve the final design in various shapes and dimensions. This technique can be used to produce a wide variety of precision components. Common CNC machine tools include vertical milling machines, horizontal milling machines, lathes, and gantry milling machines.

How does CNC machining work?

Our engineers first use the CAD files you provide to build a 3D model of the part. This model is then imported into CAM software, where they select the appropriate cutting tools based on the drawing’s critical dimensions, tolerances, and features, and configure the cutting parameters (spindle speed, feed rate, depth of cut) along with an optimal toolpath strategy. The CAM software generates a series of standardized instructions (G code, M code, etc.) that precisely control the machine’s axis movements, spindle operation, coolant flow, and tool changes. Once the CNC machine receives these codes, it moves and rapidly rotates the cutting tool according to the instructions, removing material at the correct locations until the part is fully machined.

Why choose CNC machining?

CNC machining offers a series of decisive advantages, making it the preferred method for precision parts manufacturing: it consistently achieves micron level tolerances (±0.005 mm or better) in both single prototypes and production runs, ensuring every part fully meets your specifications. It provides the capability to machine complex geometries and supports rapid prototyping through to low volume production, thereby shortening lead times and reducing labor costs. Additionally, CNC machining is compatible with a wide range of materials—including aluminum, copper, titanium, and plastic composites—which explains its widespread popularity.

What materials can be used with CNC machining?

CNC machining is compatible with a wide range of materials—including aluminum, copper, stainless steel, titanium, as well as various engineering plastics and composites. For a comprehensive list of available materials or to discuss your specific requirements, please feel free to contact us.

What’s the cost of your CNC machining parts?

CNC machining costs are primarily driven by material expenses, machining time, order quantity, and process complexity. For an accurate cost assessment, please provide your CAD drawings, PDF files, or 3D models, and we will deliver a detailed manufacturing analysis report and quotation within a few hours.

Applications of CNC Machining

CNC Precision Machining Solutions for the Automotive industry

CNC Precision Machining Solutions for the Automotive industry, CNC precision machining plays a vital role in the automotive manufacturing sector, widely used for custom components, small-batch production, and prototype development. With its high accuracy and efficiency, CNC machining offers virtually no limitations on order quantity, allowing for rapid turnaround from prototyping to production. Utilizing advanced CAD/CAM software, 3D design files are directly imported into CNC equipment, enabling a highly automated and consistent manufacturing process that significantly reduces manual errors and costs. We are capable of machining a wide range of automotive parts, including structural components, functional parts, and connectors — all produced to meet strict industry standards. If you’re looking for efficient, reliable, and flexible automotive part machining services, we are your ideal manufacturing partner.

CNC Precision Machining for the Semiconductor Industry

CNC Machining for the Semiconductor Industry, The semiconductor industry requires ultra-high precision, reliability, and material versatility to support the development of advanced electronic components. CNC machining is an ideal manufacturing solution, capable of achieving tight tolerances and consistent quality across complex geometries.

We specialize in machining a wide range of semiconductor-grade materials, including silicon, sapphire, alumina, aluminum nitride, and precision aluminum alloys. Our CNC parts are widely used in semiconductor equipment, electronic components, and integrated circuit assemblies, ensuring they meet the industry

s demanding performance and cleanliness standards. Whether for prototyping or high-precision production, we provide fast, reliable, and scalable CNC solutions tailored to the unique needs of the semiconductor sector.

CNC Machining for the Aerospace Industry

CNC Machining for the Aerospace Industry, CNC machining has been a cornerstone of the aerospace industry, delivering exceptional precision and reliability in the manufacturing of critical aircraft components. Given the stringent safety and performance requirements, the aerospace sector demands parts that meet the highest standards of accuracy, durability, and quality.At JTR Machine, we specialize in producing aerospace components with tight tolerances and complex geometries, ensuring that every part performs flawlessly in even the most demanding environments. Our extensive range of compatible materials, including aluminum alloys, titanium, stainless steel, and composite materials, allows us to meet the diverse needs of the aerospace industry.Whether for prototyping or high-volume production, we provide fast, reliable, and precise CNC machining solutions tailored to the unique challenges of aerospace manufacturing. Our commitment to quality ensures that each component meets the strictest safety and performance standards, helping you stay ahead in this high-stakes industry.

CNC Machining for the Food Industry

CNC Machining for the Food Industry, As the food industry continues to grow, the demand for high-precision, high-quality components and advanced machinery has never been greater. CNC machining is playing an increasingly important role in meeting these needs by providing custom solutions that align with the industry’s stringent standards.

With evolving regulations surrounding food safety, including contaminants, pathogens, and allergens, manufacturers must ensure their equipment is designed and produced to meet the highest hygiene and safety standards. At [Your Company Name], we follow Current Good Manufacturing Practices (CGMP) to ensure that all components and equipment meet the latest food safety regulations.

Our CNC machining capabilities allow us to produce precise, durable, and compliant components for food processing equipment, packaging systems, and more. Whether you need components that meet hygienic standards or high-performance parts designed for continuous operation, we provide fast, reliable, and customized machining solutions to support the needs of the food industry.

CNC Machining for the Medical Industry

CNC Machining for the Medical Industry, CNC machining is a critical technology in the medical industry, offering the precision, quality, and consistency required to meet the stringent standards for medical devices and equipment. Whether it’s for complex surfaces or intricate geometries, CNC machining ensures that every part is crafted to meet the highest safety and precision requirements.

In the medical field, where there is zero tolerance for error, every component must meet exacting specifications for durability, functionality, and surface finish. At [Your Company Name], we specialize in producing high-quality, custom CNC machined parts for medical machinery, ensuring that each part is crafted to perfection with ultra-high precision and reliability.

Our expertise allows us to produce components that comply with regulatory standards and perform flawlessly in critical medical applications, from surgical instruments to diagnostic equipment. With precision, reliability, and fast turnaround times, we support the medical industry in developing cutting-edge solutions that improve patient outcomes and enhance healthcare technologies.

CNC Machining for the Military Industry

CNC Machining for the Military Industry, As a trusted and experienced CNC machining partner for the military industry, Junyu delivers high-quality, precision-engineered military components and assemblies. With a proven track record in rapid custom machining, we provide military-grade CNC parts that meet the most stringent specifications, ensuring high-level precision and accurate dimensions.

We specialize in producing a wide range of military components, from individual parts to fully assembled systems, offering reliable on-time delivery and cost-effective solutions without compromising on quality. Our CNC machining services are designed to meet the critical requirements of the military sector, ensuring that each component adheres to detailed specifications and performs flawlessly in demanding applications.

At Junyu, we are committed to providing precision machining services that enhance the performance, durability, and reliability of military equipment, ensuring trusted, safe, and efficient operations in the field.

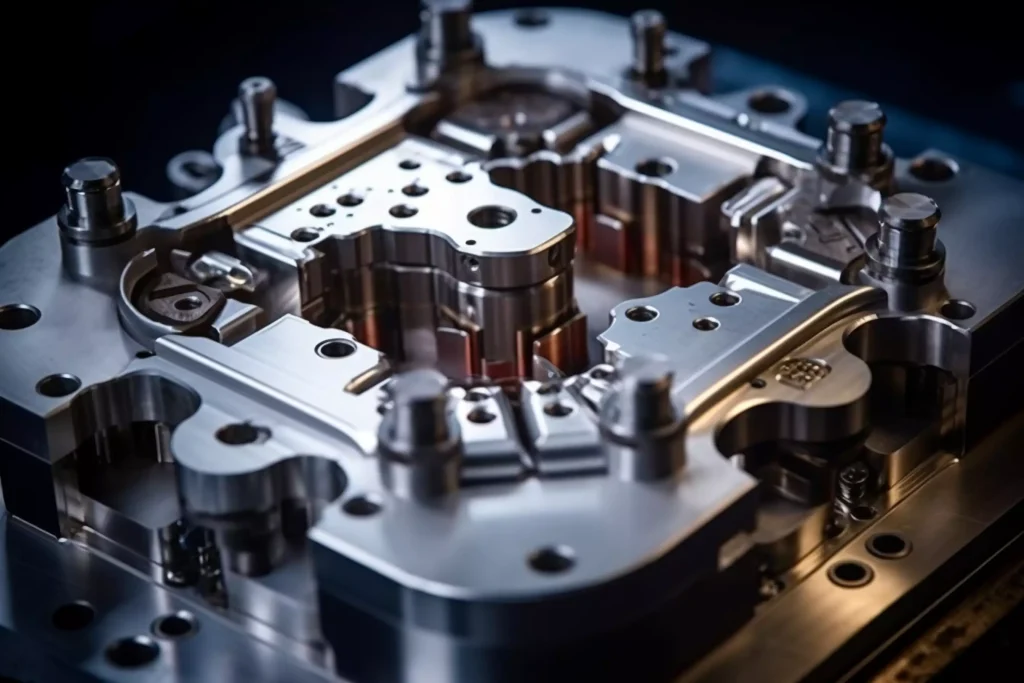

CNC Machining for the Mold Manufacturing Industry

CNC Machining for the Mold Manufacturing Industry, Mold manufacturing is essential to modern production and widely used in injection molding, die casting, blow molding, and rubber molding. As product complexity and precision requirements grow, CNC machining becomes critical for producing accurate, durable mold components. At JUNYU, we offer high-precision CNC machining tailored for the mold industry, delivering components with tight tolerances, superior surface finishes, and outstanding durability. Key Advantages High Precision – Perfect for complex cavities and tight fits Excellent Finish – Reduces polishing and improves mold release Material Flexibility – Machining P20, H13, S136, NAK80, SKD61, and more Fast Turnaround – From prototyping to small and large batch production We Machine Mold bases, cavities, and cores Ejector plates, sliders, and lifters Cooling channels and copper inserts Custom components for injection, die casting, and compression molds Why JUNYU With advanced equipment and deep expertise, JUNYU delivers precision mold components—fast and reliably, from one-off prototypes to full production. Contact us to see how our CNC machining services can enhance your mold manufacturing projects.

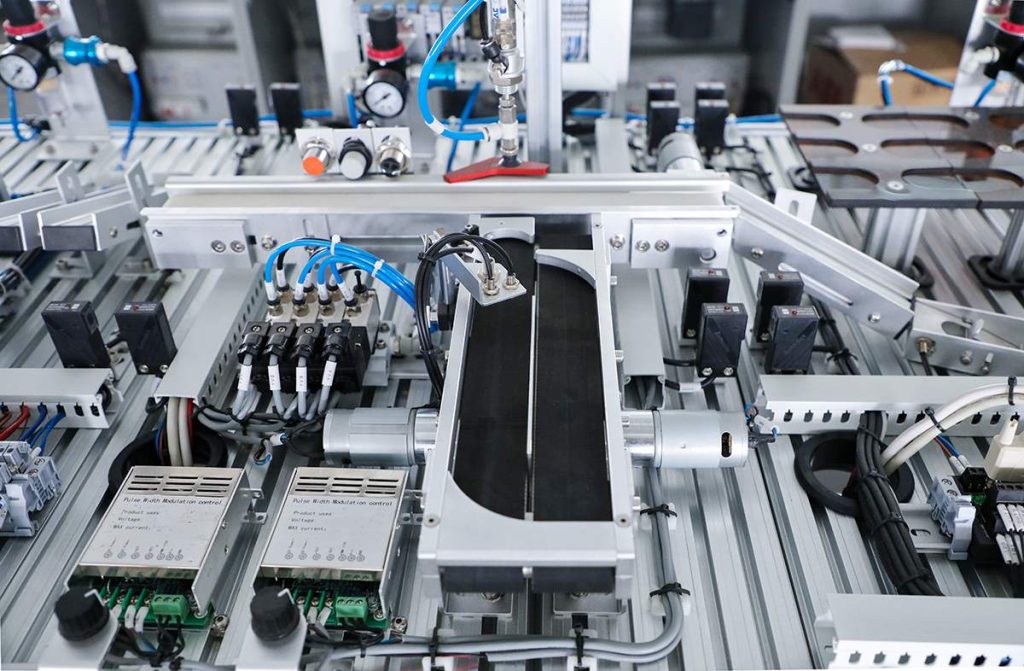

CNC Machining for the Machinery Manufacturing Industry

CNC Machining for the Machinery Manufacturing Industry, The machinery manufacturing industry relies on high-precision, durable components to ensure equipment performance and safety. From automation to heavy-duty systems, CNC machining is essential for delivering consistent, high-quality parts. At JUNYU, we provide custom CNC machining for machinery makers, producing everything from complex components to complete assemblies with speed and precision. Applications: • Industrial Equipment: Gear housings, shafts, brackets • Automation Systems: Robotic arm and actuator parts • Construction Machinery: Hydraulic fittings, bushings • Packaging & Food Equipment: Clean-finish metal components • Agricultural Machinery: Custom parts for farm equipment Why Choose JUNYU? • Micron-Level Precision for tight tolerances • Material Versatility: Steel, aluminum, brass, titanium, plastics • High Durability under tough conditions • Fast Turnaround: From prototypes to volume production We help manufacturers stay ahead with reliable, high-performance CNC solutions. Contact us to learn how we can support your next project with precision and efficiency.

CNC Machining for the Construction Industry

CNC Machining for the Construction Industry, The construction industry demands components that are precise, durable, and capable of withstanding harsh environments. CNC (Computer Numerical Control) machining plays a vital role in producing high-quality parts for various construction applications.

Key Applications

Prefabricated Components: CNC machining enables the production of accurate and consistent parts for prefabricated building elements, ensuring seamless on-site assembly.

Architectural Features: Complex designs such as moldings, facades, and decorative elements are efficiently crafted with CNC machines, enhancing aesthetic appeal.Frog3D

Structural Steel Fabrication: Precision-cut steel components like beams and trusses are manufactured to exact specifications, reducing the need for on-site modifications.

Concrete Form work: CNC technology allows for the creation of intricate and curved concrete forms, surpassing traditional methods in accuracy and efficiency.Benefits of CNC Machining

High Precision: Ensures components meet exact design specifications, enhancing structural integrity.

Efficiency: Automated processes reduce production time and labor costs, accelerating project timelines.

Customization: Facilitates the creation of bespoke components tailored to unique architectural designs.

Material Versatility: Capable of machining a wide range of materials, including steel, aluminum, wood, and composites.

By integrating CNC machining into construction processes, companies can achieve higher accuracy, improved efficiency, and greater design flexibility.

Contact us to learn how our CNC machining services can enhance your construction projects.

CNC Machining for the Electronics Industry

CNC Machining for the Electronics Industry, The electronics industry requires high-precision, compact, and reliable components for devices such as circuit boards, enclosures, and thermal systems. CNC machining ensures tight tolerances, complex geometries, and clean finishes—ideal for high-performance electronic products.

At JUNYU, we provide custom CNC machining for a wide range of electronic applications, from prototypes to full production.

Common Applications:

PCB enclosures and housings

Heat sinks and thermal management parts

Connector and interface components

Custom aluminum, plastic, and magnesium alloy parts

Why CNC for Electronics?

Precision for miniaturized components

Excellent Surface Quality for external parts

Material Versatility

Fast Turnaround for product development and scaling

JUNYU delivers reliable CNC solutions to help electronic manufacturers meet the demands of innovation and efficiency.

Contact us to learn more about how we can support your next electronics project.

CNC Machining for the Energy Industry

CNC Machining for the Energy Industry, The energy industry demands components that are precise, durable, and capable of withstanding extreme conditions such as high temperatures, pressure, and corrosion. CNC machining plays a vital role in producing reliable parts for power generation, oil & gas, renewable energy, and nuclear applications.

At JUNYU, we provide high-precision CNC machining for a wide range of energy equipment, offering fast, consistent, and cost-effective solutions.

Typical Applications:

Wind Energy: Turbine shafts, gear housings

Solar Power: Mounting brackets, heat sinks

Oil & Gas: Valves, flanges, drill components

Nuclear: Reactor parts, shielding components

Why Choose CNC Machining?

Tight Tolerances & Consistency

Materials: Stainless steel, titanium, Inconel, aluminum

Long-Term Durability

Fast Prototyping & Scalable Production

JUNYU helps energy companies achieve safe and efficient operations through reliable CNC precision manufacturing.

Contact us to learn how we can support your next energy project.

CNC Machining for the Consumer Electronics Industry

CNC Machining for the Consumer Electronics Industry, The consumer electronics industry demands compact, high-performance devices with precise, high-quality components. CNC machining is essential for producing parts with tight tolerances, complex designs, and excellent surface finishes—ideal for today’s sleek and functional products.

At JUNYU, we offer custom CNC machining tailored to the electronics sector, delivering precise parts for:

Smartphone frames and housings

Laptop and tablet enclosures

Wearable device components (e.g., smartwatches, earbuds)

Heat sinks, connectors, and precision buttons

Aluminum and magnesium alloy casings

Why CNC for Electronics?High Precision for compact assemblies

Smooth Surface Finish for visible components

Material Flexibility: Aluminum, stainless steel, plastics, etc.

Supports Prototyping & Mass Production

From prototypes to production, JUNYU ensures the precision and quality you need to bring your electronics to market faster.

Contact us to learn how our CNC services can support your next innovation

FAQ

Try JUNYU Out Now In Just A Few Steps

Upload your 2D/3D files

Choose the process

Order your parts online

Receive your parts