What Is a Progressive Stamping Die?

Progressive Die (also known as Multi-Station or Progressive Stamping Die)A progressive die is a key type of stamping tool used for sheet metal processing. It is a multi-station die in which multiple stamping operations are arranged sequentially within a single die set. As the metal strip is continuously fed through the die at a fixed pitch, each station performs a specific operation—such as piercing, blanking, bending, drawing, or cutting—in synchronization with each press stroke. At the final station, the finished part is separated from the strip.

In simple terms, a progressive die functions like a “production line within a mold.”

Instead of using multiple separate dies and manual handling between processes, it integrates all operations into one tool, with the material moving automatically and progressively through each station. This allows for high-efficiency, high-volume manufacturing without manual intervention during the process.

Progressive dies are especially suitable for mass production of small and complex metal parts, offering excellent productivity, consistency, and cost-effectiveness.

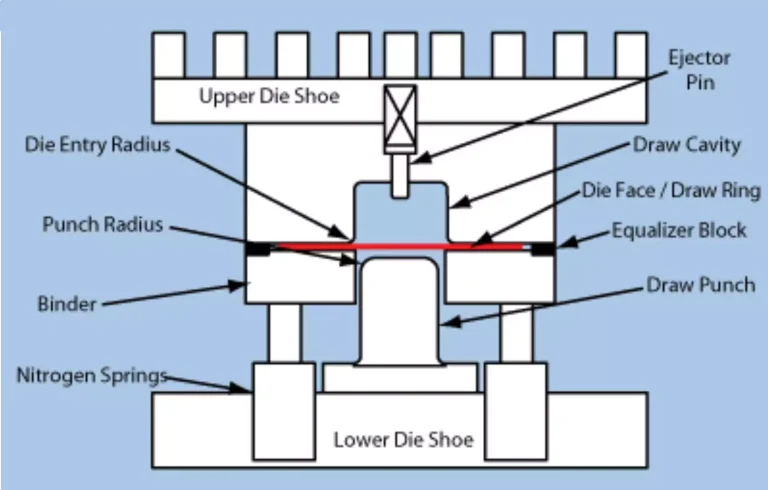

Typical Structure of a Progressive Stamping Die

Typical Structure of Progressive Stamping Dies (Progressive Die / Multi-Station Die)

A progressive stamping die is designed around the concept of multi-station sequential forming, enabling raw strip material to be incrementally transformed into finished parts as it advances through each stage. The die structure typically consists of the following key components:

1.Upper Die & Lower Die

Upper Die: Houses the punches and connects to the press ram; it performs downward stamping actions during each press stroke.

Lower Die: Holds the die inserts and guiding components, mounted on the press bed.

2.Punch & Die Inserts

The core forming elements at each station, responsible for operations such as piercing, bending, blanking, etc.

Made of high-hardness tool steels (e.g., DC53, SKD11), and typically undergo heat treatment and surface coating to enhance wear resistance.

3.Strip Guiding Components

Guide Plate: Directs the metal strip into the die smoothly and consistently.

Pilot Pin: Engages with pre-punched holes in the strip to ensure high-precision feed alignment at critical stations.

4.Progression Pitch & Layout System

Pitch: The fixed feed distance per stroke (e.g., 10mm, 15mm, 25mm), which must align with the product size and sequence of operations.

Station Layout: Determines the compactness of the die, material utilization efficiency, and process integration.

5.Stripper & Pressure Pads

Stripper Plate: Ensures proper release of material from the punches after forming, preventing material sticking.

Pressure Pad: Stabilizes the strip during forming to prevent distortion or misalignment; often supported by springs or nitrogen cylinders.

6.Guide Post System

Guide Posts & Bushings: Maintain precise alignment between the upper and lower die, ensuring the punch enters the die cavity accurately and concentrically, even at high speed.

This is critical for tool life and dimensional accuracy.

7.Scrap Discharge System

Scrap generated by punching or blanking operations is removed via slug holes, and in some designs, assisted by air blowers or automated scrap rewinding mechanisms.

This helps maintain a clean working environment and ensures uninterrupted production.

8.Die Plates & Base System

Includes components such as the upper die shoe, lower die shoe, punch holder, and die insert plate.

Provides a rigid and impact-resistant base, essential for structural integrity and long-term die stability.

9.Optional Auxiliary Mechanisms

Springs / Nitrogen Cylinders: Offer elastic force for stripping or pressure holding functions.

Sensors & Safety Devices: Such as strip break detection, mis-punch detection, or foreign object sensors, especially in precision progressive dies

Core Features of Progressive Stamping Dies

The core advantages of progressive stamping dies (also known as multi-station or sequential dies) stem from their principles of continuous operation and integrated design. These features enable highly efficient, precise, and scalable manufacturing of complex metal components. The key features include:

1.Integrated Multi-Station Layout

Each workstation is arranged in sequence according to the forming process. The raw material is gradually shaped within the die as it advances through the defined pitch (index length).

Operations such as piercing, bending, deep drawing, and cutting are integrated into a single die set.

With each press stroke, the strip advances one station, and a corresponding operation is performed—ultimately producing the finished part at the final station.

Unlike single-operation or compound dies that require manual repositioning or multiple setups, progressive dies allow “one-pass complete forming.”

2.High-Speed Continuous Production

One finished part is produced with each stroke of the press.

In conjunction with automated feeding systems, progressive dies can achieve 200–600 strokes per minute, and even higher for precision micro-components.

This results in production efficiencies several times greater than single-operation dies—especially ideal for mass production of over one million pieces, such as electronic terminals or automotive brackets.

3.Precise Indexing & Consistent Quality

The combination of pitch control and pilot pin positioning ensures each operation is executed at the precise location, avoiding cumulative error.

Parts manufactured exhibit excellent dimensional repeatability, making this method well-suited for precision metal components.

4. Reduced Labor & Lower Operational Costs

The entire stamping process is fully automated, from material feeding to part ejection.

No manual handling between stages is needed.

This reduces tooling setups, transportation time, labor requirements, and associated costs.

5.Optimized Material Usage

Through optimized nesting layouts (e.g., staggered or nested arrangements), material utilization is maximized and scrap minimized—especially important for precious metals or thin stock.

Additionally, progressive dies avoid the repeated clamping losses found in single-station operations, further reducing waste.

Scrap is discharged in a controlled manner, facilitating centralized handling or recycling.

6.High Design Complexity & Technical Demands

Progressive dies require excellent structural rigidity, high fit and motion accuracy, and fatigue resistance.

Their design and manufacturing involve precision machining (e.g., wire EDM, CNC, EDM), heat treatment, and multi-disciplinary integration including die flow simulation and stress analysis.

7.Broad Application Scope

Widely used in multiple industries, including:

- Electronics & Electrical: Terminals, connector shells

- Automotive: Clips, brackets, reinforcements

- Home Appliances: Shell reinforcements, support elements

- Medical & Instrumentation: Precision hardware components

- Daily Hardware Products

8. Ideal for Complex, Small-Sized High-Volume Parts

Progressive dies are especially advantageous for small, intricately shaped parts with high dimensional requirements—such as electronic terminals, motor contact springs, or automotive fasteners.

When parts require three or more operations (e.g., piercing + bending + trimming) and annual volumes exceed 100,000 units, the cost and efficiency benefits of progressive stamping become significantly superior.

Process Flow of Progressive Die Stamping

1.Raw Material Preparation

Metal coil stock—such as cold-rolled steel, stainless steel, copper, or aluminum—is typically supplied in roll form.

Material thickness, dimensional tolerance, and surface quality are inspected to ensure compliance with die design specifications.

2.Decoiling & Straightening

The metal coil is uncoiled using a decoiler and then passed through a straightening machine to eliminate internal stress and curvature.

This ensures the strip remains flat and properly aligned during the feeding process.

3.Automatic Feeding

A servo feeder (NC feeder) advances the strip into the die with high precision, based on the pre-set progression pitch (e.g., 10mm, 15mm, etc.).

The feeding is synchronized with the press stroke, ensuring exact alignment with each die station.

4.Positioning & Pilot Pin Correction

Pilot pins in the die engage pre-punched pilot holes on the strip to correct positioning and eliminate cumulative feed errors.

This step is especially critical for high-precision multi-station stamping parts.

5.Multi-Station Stamping Process

With each press stroke, the strip progresses through several stations to sequentially perform operations. The process typically includes:

Initial stations:

Pre-piercing (creating pilot or functional holes)

Notching (cutting side openings or clearance features)

Coining or embossing (reinforcing material locally)

Intermediate stations:

Incremental forming operations such as bending, flanging, drawing, or embossing, applied in stages to avoid material cracking from over-forming.

Final stations:

Trimming, flattening, and reshaping for dimensional refinement

Cutting-off or blanking to separate the finished part from the carrier strip

6. Part Ejection

The finished part is fully separated at the last station and automatically ejected by gravity or mechanical ejectors into a receiving container or conveyor—completely eliminating the need for manual handling.

7. Scrap Discharge

Pierced slugs and edge scrap are discharged through slug holes and can be removed using air blowers, magnetic conveyors, or scrap winders.

This ensures a clean die interior and uninterrupted production.

8. In-Line Inspection (Optional)

For precision parts, the die can incorporate sensors, optical cameras, or mechanical detectors to monitor issues such as strip breakage or missing features.

This enhances quality control within automated production lines.

9. Post-Processing & Packaging

Parts may undergo cleaning, deburring, or surface finishing (e.g., plating or coating) as required.

Products are then sorted, counted, and packaged for storage or delivery.

Professional Mold Manufacturing Workshop

Our mold workshop is equipped with a full range of advanced equipment, including high-speed CNC machining centers, precision wire-cutting machines, and mirror EDM machines. These machines are imported from Taiwan, Switzerland, and Japan, ensuring exceptional precision and consistent quality in mold manufacturing.

All production processes are completed in-house, significantly shortening lead times and improving overall project responsiveness.

The workshop is staffed with over 60 highly skilled mold technicians, most of whom have more than 10 years of experience in mold manufacturing. They are well-versed in a wide range of processing techniques and are capable of optimizing cost and efficiency at every stage of the production process.

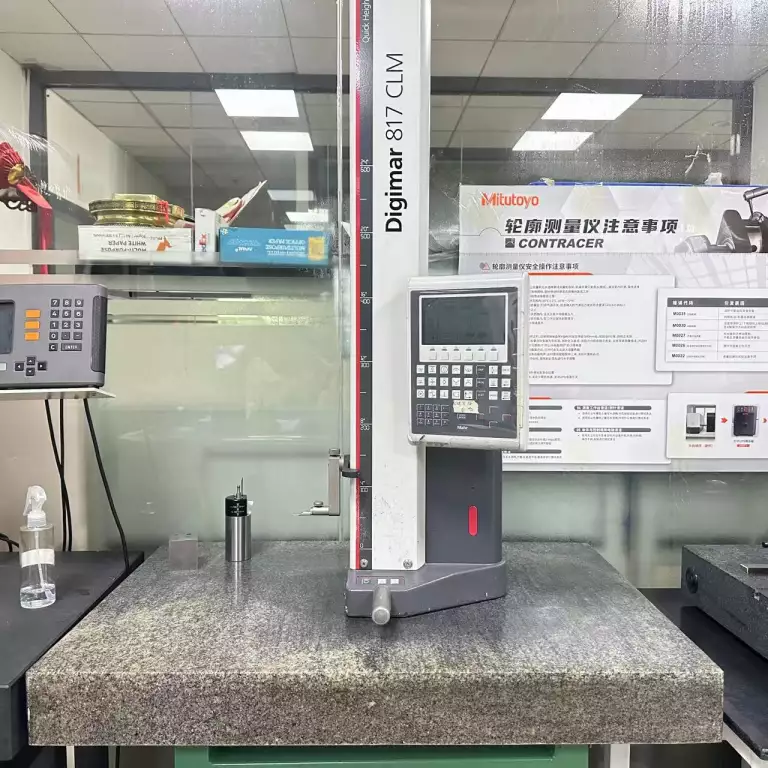

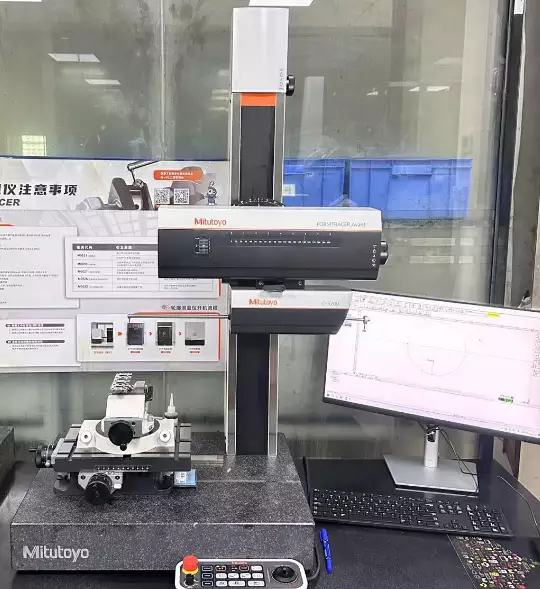

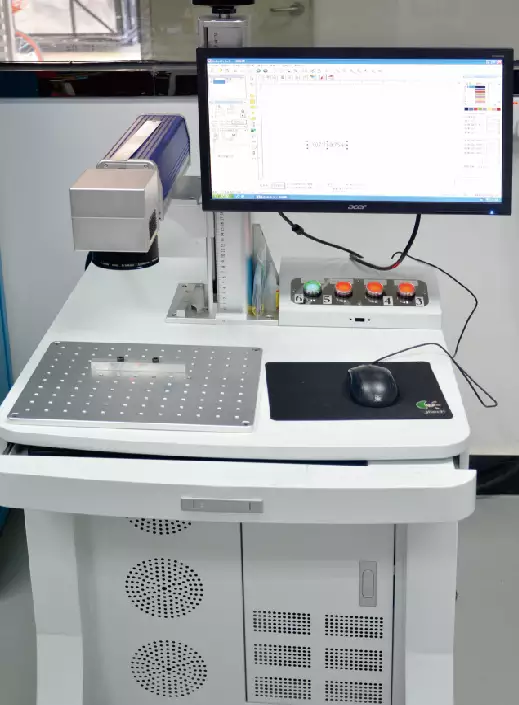

Comprehensive Mold Manufacturing Technical Support

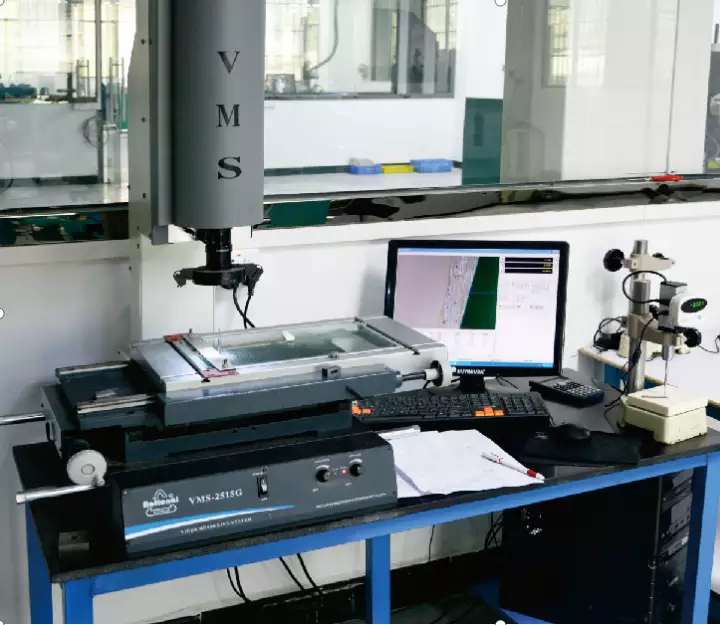

Hexagon 3D Measuring projector

Zeiss 3D Measuring projector

Micro Altimeter

Nikon projector

Nikon tool microscope

Mitutoyo Contour

Laser marking machine

Nikon Altimeter

2D Measuring Projector

As a quality-conscious company, we ensure the accuracy of molds and parts through rigorous dimensional inspections and conduct all necessary additional testing on the molds. We offer comprehensive technical support, perform repairs and rebuilds as needed, and maintain detailed records of all maintenance activities in the mold history. With flexible production methods and a strong focus on customer service, we are able to complete most molds within one to two weeks and provide expedited services for urgent projects. As a professional company, we are committed to listening to our customers’ needs and providing solutions that enhance product quality. For more information on our mold manufacturing capabilities or to request a quote, please contact us directly.

Types of Progressive Dies

Progressive stamping dies can be categorized based on their structural design, forming complexity, material applicability, and precision level. The following are the main types:

1.Standard Progressive Die

- Structure: Typical multi-station layout performing sequential operations such as piercing, bending, forming, and cutting.

- Application: Suitable for medium-complexity parts made of common materials like cold-rolled steel or copper.

- Advantage: Versatile, relatively short manufacturing lead time, ideal for medium-batch production.

2.Compound Progressive Die

- Feature: Multiple operations are performed simultaneously at certain stations (e.g., piercing + bending).

- Benefit: Reduces the number of die stations and overall die length, increasing material utilization and throughput.

- Application: High-efficiency production of electrical and hardware components.

3.Drawing-Type Progressive Die

- Structure: Incorporates multi-stage deep drawing operations along with blanking and trimming.

- Material: Suitable for materials with good drawability, such as stainless steel or aluminum.

- Application: Used for housings, end caps, battery shells, and other deep-drawn parts

4.High-Precision Progressive Die

- Precision: Die manufacturing tolerance ≤ ±0.005 mm; feeding repeatability ≤ ±0.01 mm.

- Configuration: Includes high-rigidity guide posts and in-die sensors (pneumatic or optical).

- Application: Micro metal components such as connector terminals, motor springs, and electronic pins.

- Feature: Designed for high-speed presses (300–800 SPM).

5.Double-Strip Progressive Die

- Structure: Processes two metal strips simultaneously in left-right symmetry.

- Advantage: Doubles productivity in a compact footprint.

- Application: Suitable for symmetrical parts such as connectors or contact blades.

6.Reverse Progressive Die

- Feature: The material strip undergoes reverse feeding or operations in reverse direction.

- Challenge: Complex die structure and high alignment accuracy required.

- Application: Special parts with reverse bending, flanging, or locking features.

7.Multi-Product Progressive Die

- Feature: Capable of producing 2 to 4 different components simultaneously in a single die.

- Key: Requires precise strip layout and synchronized feeding and part ejection.

- Application: Manufacturing of small, structurally related part families.

8.Hot Progressive Die

- Structure: Incorporates heated forming zones for hot stamping of materials like ultra-high strength steel or titanium alloys.

- Application: Automotive reinforcement components and aerospace-grade parts.

- Challenge: Requires heat-resistant tool steels and thermal insulation, with stringent lifespan and safety requirements.

Industries We Serve

electronics and telecommunication industry

medical device industry

home appliance and smart home industry

automobile manufacturing industry

new energy and photovoltaic industry

electronics and telecommunication industry

hardware and daily necessities industry

aerospace and military industry

FAQ

How long does it take to deliver the mold?

The delivery time depends on the complexity of the mold, typically ranging from 15 days to several months.

How long will the shipping take?

If shipped by sea, the transportation time may exceed one month. If you need the mold urgently, we recommend choosing air transport to shorten delivery time.

Can we sign an NDA before uploading my design?

Of course, we take your design confidentiality very seriously.

What should I pay attention to when designing a mold?

Pay attention to factors such as product structure and functionality compatibility, accuracy and tolerance control, material selection and heat treatment, gating and cooling system design, maintainability and cost control, as well as production efficiency and automation compatibility.