Mold Making Service

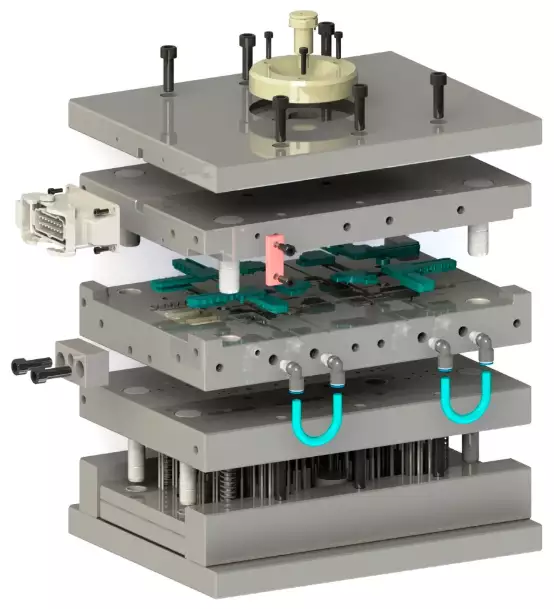

Nearly 100% of our mold manufacturing is completed in-house, using materials such as tungsten steel, standard steel, aluminum, and composites.

We are capable of producing a wide range of molds, including injection molds, metal stamping molds, powder metallurgy molds, and blow molds.

Our mold manufacturing department is equipped with advanced and comprehensive machinery, ensuring high efficiency and precision.

With an experienced team in design, engineering, and manufacturing, we provide one-stop custom mold and molding solutions tailored to your specific needs.

With over 15 years of experience in mold manufacturing (including injection molds, stamping molds, and powder metallurgy molds),

we specialize in complex mold design with delivery in as fast as 7 days.

We offer competitive pricing while ensuring superior quality.

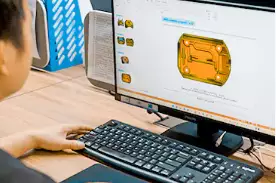

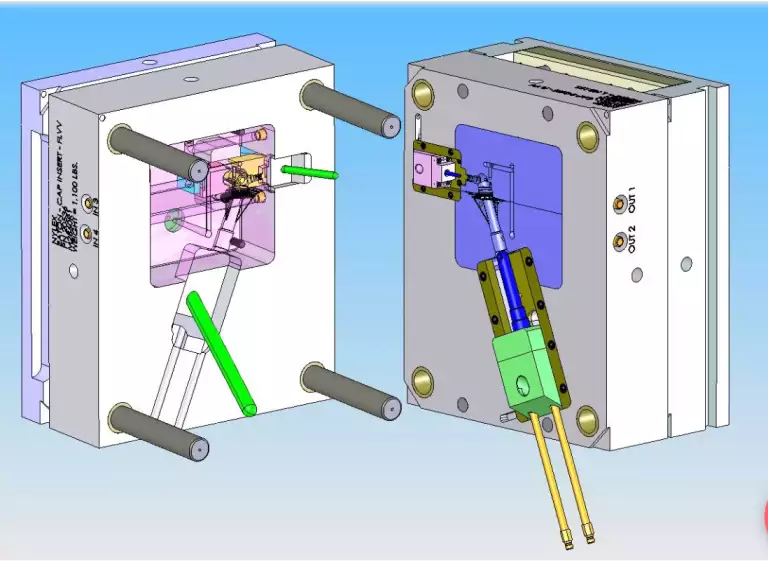

Mould Design Capability

Mold Manufacturing is the Core Business of JUNYU. At JUNYU, high-quality mold manufacturing is at the core of our operations. We have a professional team of 10 senior mold design engineers with extensive experience in material properties and mold structures. With over a decade of expertise in delivering high-end custom mold solutions, our team is dedicated to treating every project with the utmost care and precision.

Before initiating any design work, our design team conducts mold flow analysis and participates in technical review meetings with the tooling workshop and relevant departments. This allows us to anticipate and eliminate potential manufacturing risks, ensuring design feasibility and seamless process integration. This standardized workflow is a key foundation for our consistent high-quality delivery and rapid turnaround times.

Our design services include:

- Industrial Design

- Appearance Design

- Structural Design

- Mold Design (2D & 3D)

- Mold Flow Analysis

Experienced Mold Making Team

JUNYU has a team of mold design and process engineers with over 10 years of industry experience. Proficient in a wide range of molding processes such as injection molding and stamping, our engineers are well-versed in complex mold structures including hot runner systems and multi-slide mechanisms. Based on the unique characteristics of each product—such as high-precision gears or thin-walled components—our engineers can deliver customized designs and structural optimizations to achieve the optimal balance between molding efficiency, product accuracy, and tool longevity.

Our facility is equipped with a full range of high-precision machining equipment, including CNC machining centers, precision EDM machines, slow wire-cut machines, and optical grinding projectors. We also have a dedicated polishing department to ensure that mold dimensional tolerances and surface finishes meet the most stringent standards required for precision tooling.

In the mold industry, precision is only the starting point—what truly defines competitiveness is the ability to deliver high-quality molds consistently and reliably. JUNYU has established a comprehensive quality control system, implementing rigorous traceability and inspection protocols throughout the entire manufacturing process. Over the years, we have built long-term partnerships with clients from Japan, Europe, and other high-standard markets. Our molds are widely recognized for their precision, stability, and durability—testaments to JUNYU’s strength and reputation in high-end mold manufacturing.

Mold Making Process

1. Requirements Meeting

A meeting is held to thoroughly discuss mold production requirements and address related technical issues, including material selection, structural functionality, product appearance, application environment, and inspection standards. This ensures clear project goals and smooth communication.

2. Mold Design and Flow Analysis

We use advanced simulation software to predict the flow behavior of molten material within the mold cavity. This analysis helps optimize mold design parameters to achieve the goals of high quality, low cost, and short lead time.

3. CNC Machining

According to the design drawings and production schedule, we use high-precision CNC equipment to efficiently machine mold components, ensuring dimensional accuracy and structural stability.

4. Sample Making (T1 Sample)

The first T1 sample is produced to verify whether the customized part meets the design specifications in terms of dimensions, functionality, and appearance. This is a critical step in the mold development process.

5. Inspection and Feedback

We conduct a comprehensive inspection of the sample’s shape, dimensions, color, and surface quality. Results are reviewed together with the client, and the mold design is refined as needed based on customer feedback.

6. Finalization and Production

Once the sample is approved by the client, a small batch trial production is carried out to ensure mold stability and product consistency. Full-scale injection molding production then begins.

7. Delivery

We ensure the mold is properly protected during packaging to maintain its appearance and structural integrity. Molds are carefully stacked on pallets, and shipment is arranged only after final client approval, guaranteeing safe and timely delivery.

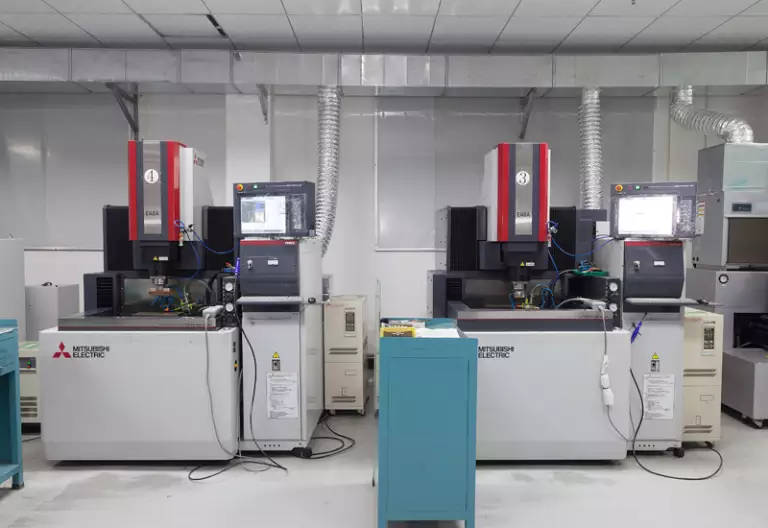

Professional Mold Manufacturing Workshop

Our mold workshop is equipped with a full range of advanced equipment, including high-speed CNC machining centers, precision wire-cutting machines, and mirror EDM machines. These machines are imported from Taiwan, Switzerland, and Japan, ensuring exceptional precision and consistent quality in mold manufacturing.

All production processes are completed in-house, significantly shortening lead times and improving overall project responsiveness.

The workshop is staffed with over 60 highly skilled mold technicians, most of whom have more than 10 years of experience in mold manufacturing. They are well-versed in a wide range of processing techniques and are capable of optimizing cost and efficiency at every stage of the production process.

Precision Mold Parts Machining Equipment

At JUNYU, we firmly believe that our employees are our most valuable asset. Their expertise and dedication enable us to consistently deliver high-quality, cost-effective mold solutions to our clients.

JUNYU has comprehensive capabilities to efficiently transform product blueprints and prototypes into mass production parts, backed by deep expertise, creativity, and advanced hardware and software resources.

We are equipped with a fully functional prototyping workshop, enabling us to test and optimize newly developed molds, as well as rework and upgrade existing molds with high-quality modifications.

Our precision machining capabilities cover a full range of advanced equipment, including optical profile grinders, CNC machining centers, precision wire-cut EDM machines, high-precision EDM machines, CNC milling and turning machines, as well as precision grinding and polishing equipment. CAD design and CNC programming are integrated throughout the entire process—from prototyping to final part production—ensuring seamless coordination and high efficiency.

With this robust equipment setup, we are well-positioned to meet a wide range of customer demands for mold precision and complex geometries, ensuring efficient project execution and reliable quality assurance.

Comprehensive Mold Manufacturing Technical Support

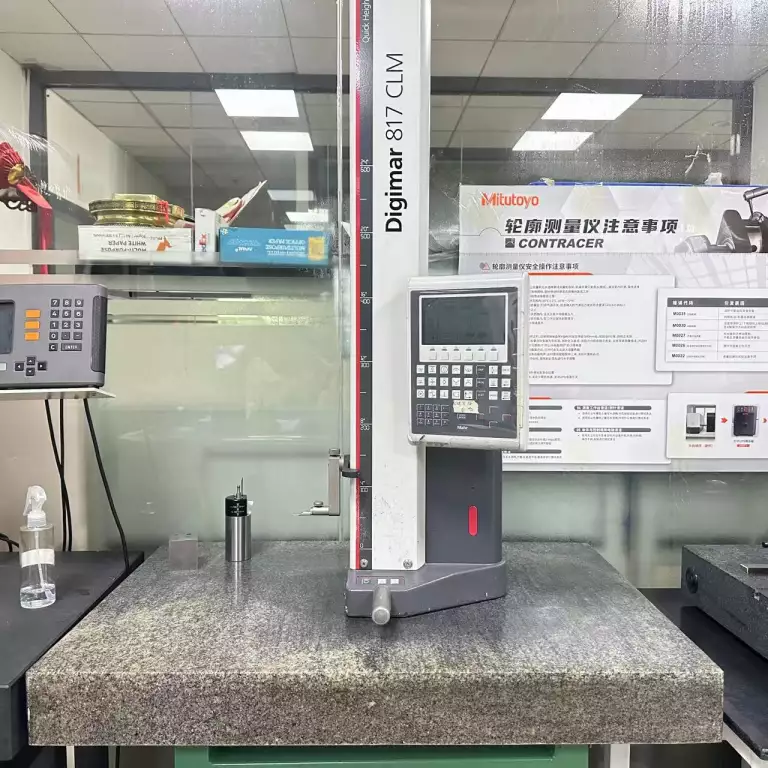

Hexagon 3D Measuring projector

Zeiss 3D Measuring projector

Micro Altimeter

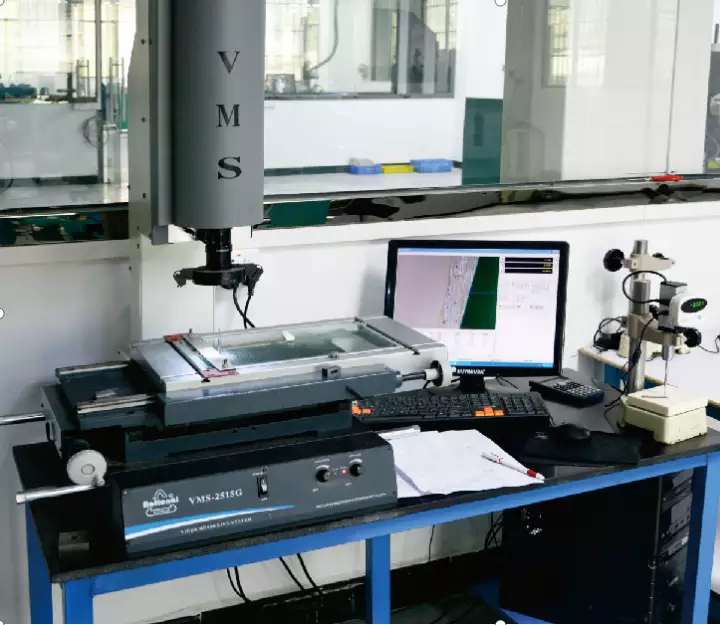

Nikon projector

Nikon tool microscope

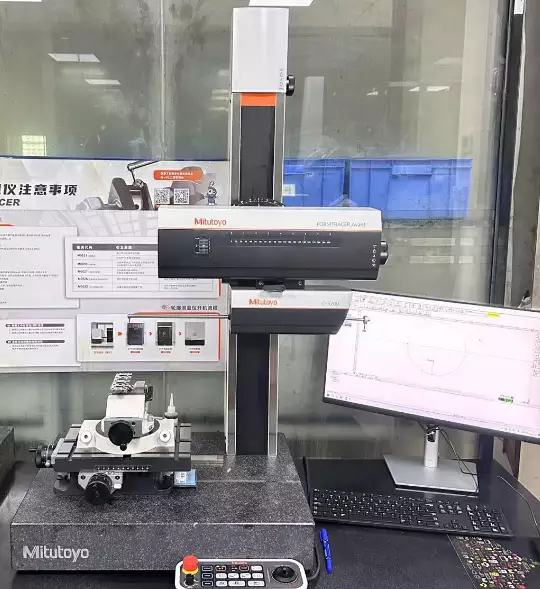

Mitutoyo Contour

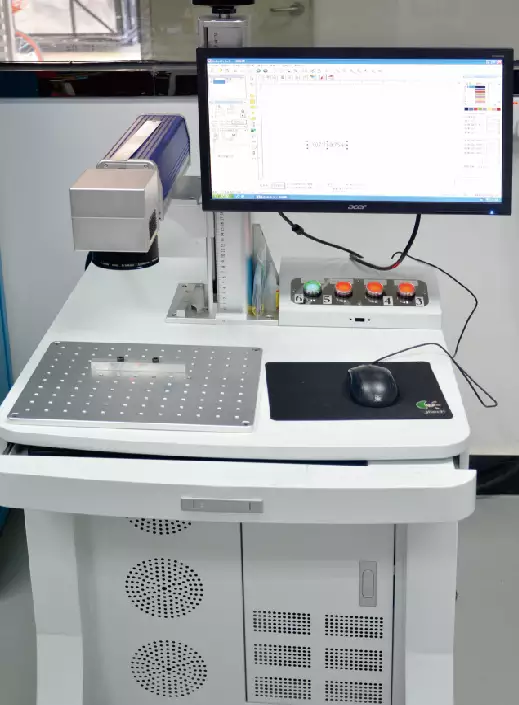

Laser marking machine

Nikon Altimeter

2D Measuring Projector

As a quality-conscious company, we ensure the accuracy of molds and parts through rigorous dimensional inspections and conduct all necessary additional testing on the molds. We offer comprehensive technical support, perform repairs and rebuilds as needed, and maintain detailed records of all maintenance activities in the mold history. With flexible production methods and a strong focus on customer service, we are able to complete most molds within one to two weeks and provide expedited services for urgent projects. As a professional company, we are committed to listening to our customers’ needs and providing solutions that enhance product quality. For more information on our mold manufacturing capabilities or to request a quote, please contact us directly.

The software we use

Our engineer mainly used the following software:

- Pro/ENGINEER

- SolidWorks

- AutoCAD

- Moldflow

- MasterCAM

- Unigraphics

- Animatronic

- Surfcam

- CATIA

One-stop Mold Manufacturing Service

Our “one-stop mold manufacturing service” covers a full range of services, including product design analysis, mold flow analysis, precision machining, assembly and debugging, and after-sales support. We also offer support and acceptance for existing molds, mold repairs, as well as comprehensive mold management and custom parts molding solutions. Regardless of the type of new mold you need, the JUNYU team always provides high-quality mold and custom parts molding services with its professional skills and exquisite craftsmanship.

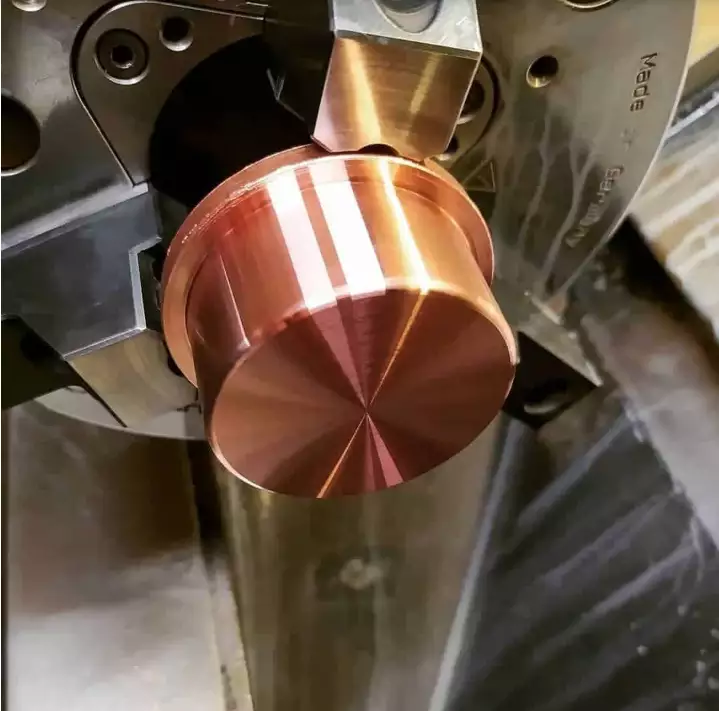

Custom Mold and Tooling Materials

The selection of precision mold materials should take into account factors such as the product material (e.g., plastic, metal), production volume (batch/large-scale production), accuracy requirements (e.g., mirror finish), and operating conditions (high temperature/corrosive environments). Choosing the right mold material can not only enhance the mold’s performance and lifespan but also effectively reduce the cost of custom molded parts. So, what material should your mold be made of? JUNYU offers a variety of custom mold materials, and our experienced team will provide professional material recommendations based on your project requirements and product development stage. Below are some of the common material types we offer.

Why Do We Recommend Test Molding?

Untested molds may lead to issues such as energy wastage during mass production (e.g., poor cooling system design causing equipment to operate under high load for extended periods) and manual rework (e.g., burrs on products requiring manual polishing). These hidden costs can accumulate and account for 15%-20% of production costs. The recommendation for mold testing is primarily to identify risks and ensure quality before mass production, achieving higher production reliability at a lower cost. Mold testing is like a “check-up” before mass production, spending a small amount to identify potential problems and ensure quality.

Moving Existing Tooling

If you have existing molds used for product production but are dissatisfied with your current supplier, JUNYU can provide a solution. We have successfully helped several clients quickly transfer their existing molds to us, minimizing the impact on the client’s part supply and subsequent production cycle. With manufacturing facilities in Dongguan, China, we can produce your products in an efficient and cost-effective manner, helping you save costs. Additionally, we conduct thorough inspections of incoming molds before production to identify any issues that may affect quality or operator safety. At JUNYU, we take great care of your molds, both during production and storage. This attention to detail ensures that your molds will consistently produce high-quality, within-tolerance parts for an extended period, without the need for rework.

Mold After-Sales service

For all types of molds exported worldwide, we provide complete technical documentation, including 2D/3D design drawings, CNC programming data, injection molding parameters, and dimensional inspection reports. In addition, we supply EDM copper electrodes, replacement blades, and other wear parts to facilitate routine maintenance and efficient servicing, ensuring long-term and stable mold performance.

Why Choose JUNYU for Tool & Mold Making?

Professional Experience

With over 10 years of mold processing experience, our team possesses a solid technical background, enabling us to provide high-quality, precise mold solutions for our clients. Whether it’s a single mold or a complex structure, we can design and process molds accurately based on your requirements.

Advanced Equipment

Our company is equipped with advanced precision processing equipment, including high-speed CNC machining centers, precision EDM machines, slow wire-cutting machines, optical projection grinding machines, and more. We can meet the high-precision and complex mold processing requirements.

Quality Assurance

We are equipped with a range of high-end inspection equipment, such as Zeiss CMM, NIKON projectors, Mitutoyo profile meters, NIKON height gauges, and NIKON microscopes. We strictly control the precision and performance of every mold part to meet the highest standards. Each processing step is carefully inspected by professionals to ensure stable product quality and delivery time.

Save Lead Time

You can work with multiple suppliers to complete the same project. For example: arrange company A for design, factory B for mold base manufacturing, factory C for core manufacturing, factory D for sliders/lifters/inserts, etc. (ensuring each supplier controls the tolerances within your required range for easy assembly), and factory E (in your country) for assembly and trial. Normally, from design, processing, fitting, trial, to final shipping, this would take at least 3 months. However, with this approach, we can complete all projects within 1 month, significantly saving lead time.

Customized Services

We offer tailored mold processing services, capable of designing and processing molds according to the specific needs of our clients. Our professional team works closely with you to ensure the mold fully meets your product requirements.

Competitive Pricing

We provide high-quality mold processing services at competitive prices, helping clients reduce costs while maintaining product quality and precision. Additionally, we offer long-term after-sales support.

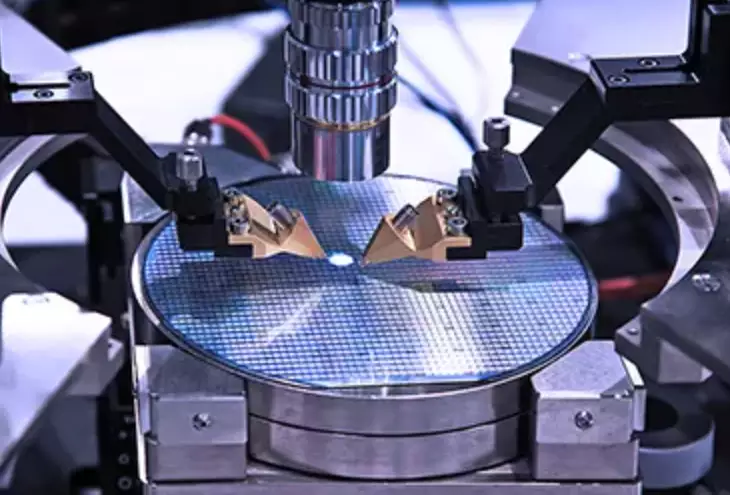

Industries We Serve

Aerospace

Industrial

Robotics

Automotive

Marine

Semiconductor

Consumer Products

Medical

Drone

New Energy

Electronics Industry

Optics

Mold Making FAQ

How long does it take to deliver the mold?

The delivery time depends on the complexity of the mold, typically ranging from 15 days to several months.

How long will the shipping take?

If shipped by sea, the transportation time may exceed one month. If you need the mold urgently, we recommend choosing air transport to shorten delivery time.

Can we sign an NDA before uploading my design?

Of course, we take your design confidentiality very seriously.

What should I pay attention to when designing a mold?

Pay attention to factors such as product structure and functionality compatibility, accuracy and tolerance control, material selection and heat treatment, gating and cooling system design, maintainability and cost control, as well as production efficiency and automation compatibility.