CNC Milling Aluminum Parts

Aluminum is a material widely used in CNC machining, known for its lightweight, softness, ease of processing, maneuverability, and durability. In addition, as a non-ferrous and non-flammable metal, aluminum offers higher safety. With a density of approximately 2.68 g/cm³, it holds a distinct advantage in lightweight structural applications. Its melting point is around 660°C, making it suitable for controlled thermal processing.

In high-precision machining fields such as automotive, aerospace, and military industries, aluminum demonstrates superior machinability and application potential compared to steel. In recent years, as technology has advanced rapidly and industries demand higher performance and lighter structural components, the use of aluminum and aluminum alloy parts has expanded significantly. Automotive manufacturers, in particular, increasingly favor aluminum alloys over traditional steel to achieve both weight reduction and cost-efficiency benefits.

JUNYU’s capability of CNC Milling Aluminum parts

| Processes | Lead Time | Tolerance | Price | Applications | Alloys | Finishing Options |

| CNC Milling | As fast as 3 days | With drawing: Precision up to +/- 0.005 mm. No drawing: ISO 2768 medium | Fees are based on the product. | Lightweight and cost-effective, CNC Lathe suitable for prototyping to mass production. | 6061, 7075, 7050, 2024, 5052, 6063, MIC6 | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

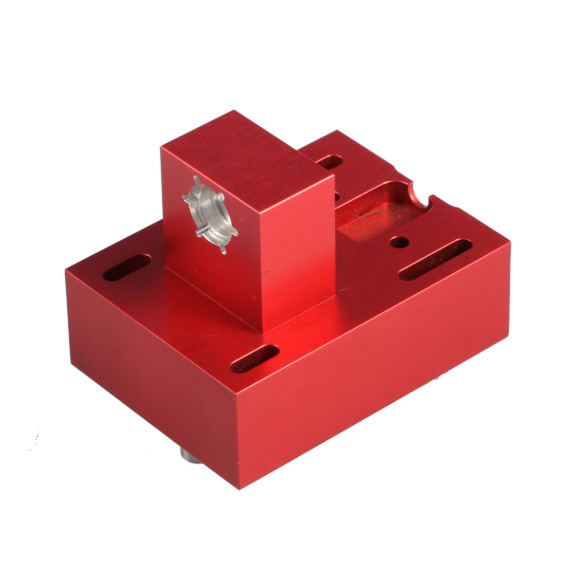

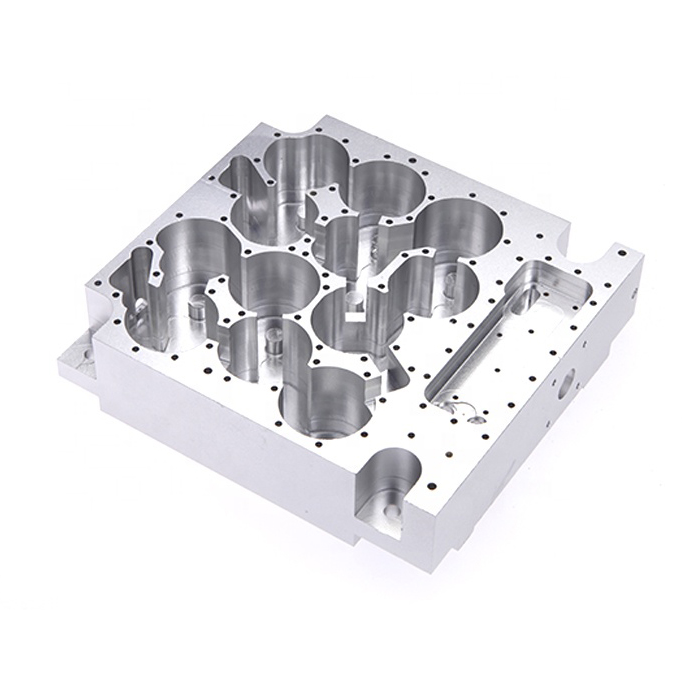

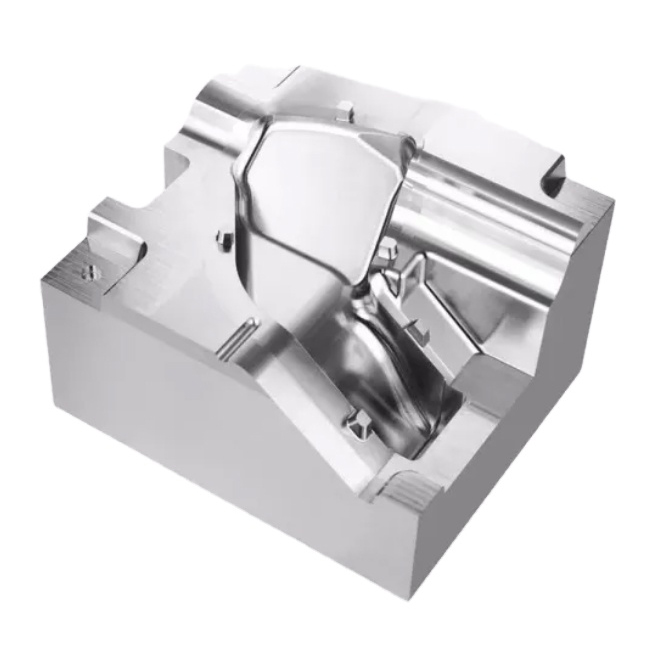

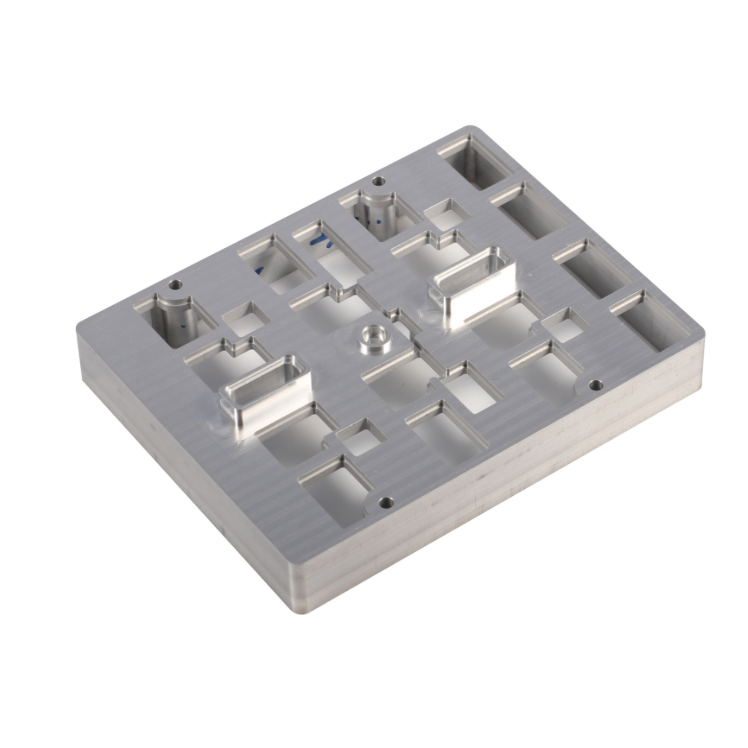

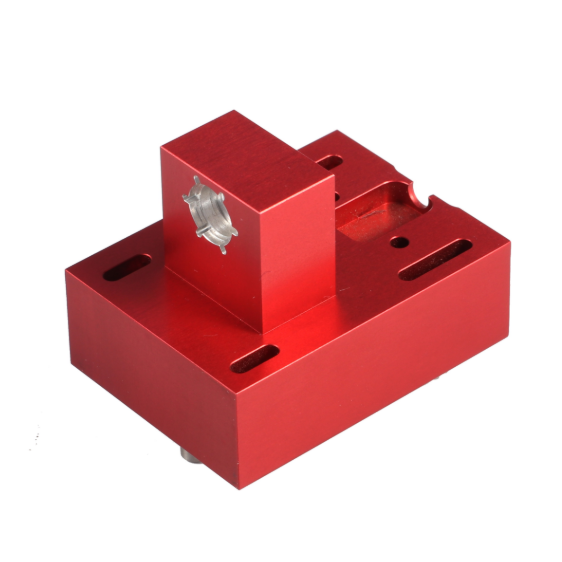

JUNYU CNC Milling Aluminum Parts

CNC Milling for Aluminum material parts

Aluminum 2024

2024 aluminum alloy is commonly used in aerospace, military, and other applications that require high strength and good corrosion resistance. It is enhanced with alloying elements such as copper, magnesium, and manganese to improve its mechanical properties. Although 2024 aluminum alloy is not as strong as 7075 aluminum, it is often selected when a high strength-to-weight ratio is required. 2024 aluminum alloy is heat treatable and non-magnetic.

| Density(p) | Electrical Conductivity | Young’s Modulus (E) | Elongation (ε) at break |

| 2.78 g/cm3 (0.1Ib/in²) | 30% | 73 GPa (10.6Msi) | 10-25% |

Aluminum 6061

The most commonly used aluminum alloy in our machining services is Aluminum 6061, a versatile and easy-to-machine metal. It offers excellent corrosion resistance, is non-magnetic, and can be heat treated.

| Tensile Strength,Yield (MPa) | Young’s Modulus (E) | Density(p) | Specific Heat Capacity (c) | Elongation (ε) at break |

| 124-290 MPa (18.0-42.1 ksi) | 68GPa (9,900 ksi) | 2.70 g/cm² | 897 J/(kg-K) | 12-25% |

Aluminum 6063

AA6063 aluminum is a common aluminum alloy, with magnesium and silicon as the primary alloying elements. Compared to 6061 aluminum, 6063 aluminum offers better corrosion resistance and formability. It is not suitable for high-strength applications but can be used for exterior railings and decorative trim. The advantage of CNC machined 6063 aluminum is that it is heat treatable and non-magnetic.

| Density(p) | Young’s modulus (E) | Tensile Strength (ot) | Elongation (ε) at break | Specific Heat Capacity (c) |

| 2.69 g/cm3 | 68.3 GPa (9,910 ksi) | 145-186 MPa (21.0-27.0 ksi) | 18-33% | 900 J/kg*K |

Aluminum 5052

5052 aluminum alloy is relatively easy to weld, with magnesium as the primary alloying element. It is easy to form, heat treatable, and non-magnetic. It has excellent corrosion resistance, especially in seawater and salt spray environments, making it the material of choice for applications with high corrosion resistance requirements in marine engineering (such as LNG tanker tanks). Its resistance to saltwater and salt spray allows it to withstand the challenges of marine environments, which is why it is widely used in marine, shipbuilding, and related industries.

Typical applications of 5052 aluminum alloy include marine, aerospace, construction, general sheet metal work, heat exchangers, fuel pipelines and tanks, flooring panels, streetlights, appliances, rivets, and wire.

| Density (p) | Volume Resis tivity(p) | Young’s Modulus (E) | Elongation (e) at break | Tensile Strength,Yield (MPa) |

| 2.68 g/cm3 | 49.3-49.9 nOhm*m | 69.3 GPa | 7-27% | 195-290 MPa (28.3—42.1 ksi) |

Aluminum 7075

7075 aluminum alloy is typically a high-strength, high-hardness alternative to 6061 aluminum alloy. It is widely used for parts in high-stress environments. Compared to 6061 aluminum, 7075 aluminum has slightly lower corrosion resistance. However, 7075 aluminum is non-magnetic and can be heat treated.

| Density (p) | Young’s modulus (E) | Tensile Strength (ot) | Elongation (ε) at break | Maximum Yield Strength |

| 2.81 g/cc (0.102 Ib/cu in) | 71.7 GPa (10,400 ksi) | 572 MPa (83.0 ksi) | 11% | 280 MPa (41 ksi) |

Our Strengths in CNC Milling

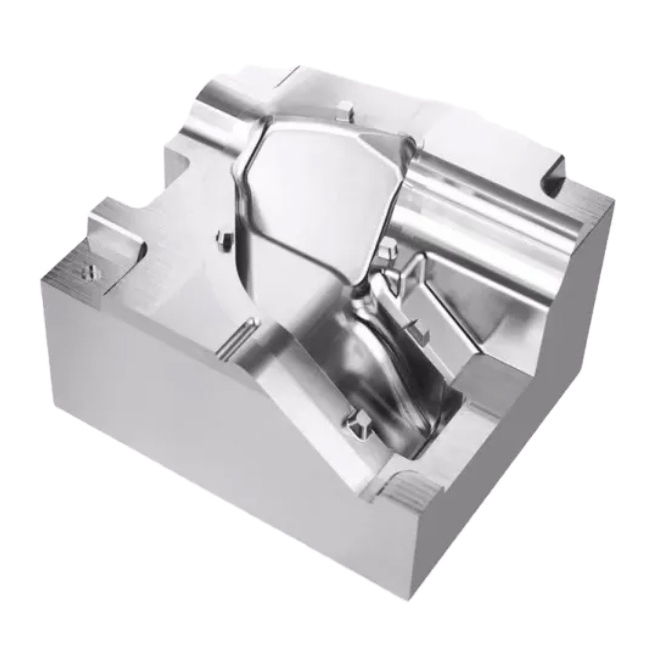

1.High Adaptability and Flexibility:Capable of machining parts with extremely complex profiles or dimensions that are difficult to control, such as precision components like molds and housings.

2.Advanced Capability for Complex Geometries:CNC milling enables the machining of intricate 3D surfaces, irregular holes, and undercut structures that are difficult or impossible to achieve with conventional methods — including mold cavities, impellers, and blades.

Through multi-axis linkage (e.g., 3-axis, 4-axis, 5-axis), the machining dimensions can be extended and the number of setups significantly reduced.

3.Integrated Multi-Process Machining:Multiple operations can be completed after a single clamping and positioning, which enhances machining accuracy and reduces clamping time and cumulative errors.

4.High Precision and Stable Quality:The pulse equivalent of a CNC system is generally 0.001 mm, and high-precision systems can achieve up to 0.1 μm. CNC machining eliminates manual errors and ensures stable, consistent processing quality.

5.Automation and High Efficiency:Once programmed, CNC machines can perform continuous operations with minimal human intervention, making them ideal for extended periods of unattended production and improving overall efficiency.

6.High Production Efficiency:CNC milling machines typically do not require specialized tooling or fixtures. When switching workpieces, operators only need to load the corresponding programs, fixture setups, and tool data from the system, which significantly shortens production cycles. Moreover, CNC milling combines the functions of milling, boring, and drilling, resulting in process consolidation and higher efficiency. The spindle speed and feed rate can be continuously adjusted, allowing optimal cutting parameters to be selected.

Reliable CNC Milling Supplier for Premium Aluminum Parts – Made in China

China is home to many top-grade suppliers specializing in precision CNC milling of aluminum parts, and JUNYU is proud to be one of them, with a strong focus on high-precision CNC machining technology.

Equipped with advanced CNC equipment, we offer comprehensive and customized turning and milling services, enabling us to produce high-precision aluminum components according to our clients’ exact specifications.

All parts are manufactured using premium raw materials sourced from well-known and trusted industry suppliers, ensuring consistent quality and reliability. Backed by a professional and experienced technical team, we ensure our machines operate at peak performance and deliver highly precise and consistent results.

In addition, our CNC-milled aluminum products strictly comply with international quality standards and are widely applied across various industrial sectors. We are committed to providing our valued customers with competitively priced and dependable aluminum CNC machining services.

Advantages of CNC Milled Aluminum Parts

1. Material Properties and Machinability

Lightweight and High Strength: Aluminum alloys (e.g., 6061, 7075) have low density yet high strength, making them ideal for aerospace and automotive lightweight components. CNC machining enables precise retention of thin-wall and hollow structures.

Excellent Machinability: With moderate hardness and good ductility, aluminum offers low cutting resistance and slow tool wear. High-speed and high-feed-rate machining is feasible, with cutting speeds reaching 3000–6000 rpm, significantly improving efficiency.

2. High Precision and Surface Quality

Tight Tolerances: Aluminum parts can be machined with dimensional accuracy within ±0.05 mm. When paired with diamond-coated tools or precision milling cutters, surface roughness (Ra) can be reduced to below 0.8 μm, meeting post-processing requirements like anodizing and electroplating.

Deformation Control: CNC machining minimizes the risk of deformation caused by manual handling, especially suitable for thin-walled parts such as smartphone frames and heat sinks.

3. Efficient Mass Production Capability

Chip Control and Cooling: Aluminum chips break easily and are easy to evacuate (when combined with coolant or air-blast), enabling continuous high-speed machining. A single CNC machine can produce several hundred parts per day, suitable for high-volume industries like 3C products and medical devices.

Multi-Axis Machining: Multi-axis CNC (e.g., 5-axis milling) allows for multi-face machining in a single setup—ideal for complex parts like aluminum impellers—reducing setup errors and process turnaround time.

4. Advantage in Complex Structure Machining

Fine Feature Machining: CNC can machine deep holes, intersecting holes, micro-slots (≥0.5 mm width), and 3D contours in aluminum parts—ideal for UAV frames. Structures difficult to achieve through casting or stamping, such as heat dissipation fins and threaded inserts, can be directly milled with precision.

5. Cost and Flexibility Benefits

No Molds Required: Unlike die casting (which requires expensive molds), CNC milling does not require tooling, allowing for rapid prototyping (1–3 days) and low-volume production—ideal for customized parts and product iterations.

Material Recycling: Aluminum chips are highly recyclable, with recovery rates exceeding 90%, reducing overall material cost.

6. Process Compatibility and Post-Processing

Excellent for Surface Treatment: CNC-milled aluminum parts can undergo various finishing processes, including anodizing (e.g., colored smartphone housings), hard anodizing (for wear resistance), and electroless nickel plating. Surface adhesion is superior to that of cast parts.