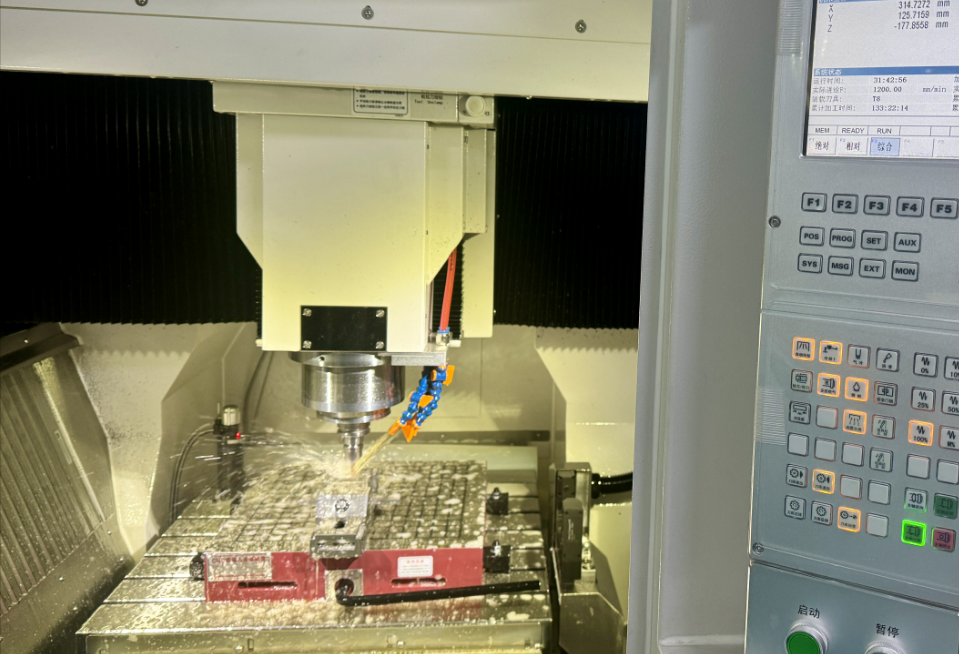

CNC Milling Steel Parts

Steel is a general term for iron-carbon alloys with a carbon content ranging from approximately 0.02% to 2.11% by mass. To meet the performance requirements of different applications, steel is often alloyed with elements such as manganese, nickel, and vanadium to form various types of alloy steel.

Thanks to its excellent mechanical properties, steel has become one of the most commonly used materials in CNC machining. CNC milling is particularly well-suited for the secondary processing of steel parts, offering high precision and good consistency.

CNC milling services for steel enable the precise machining of complex structures, including features such as drilling, slotting, and threading. The finished parts exhibit excellent dimensional accuracy and quality. As a result, CNC machining is an ideal solution for producing high-quality precision steel components, widely used across various industries.

CNC Milling for Steel Materials Parts

Steel SKD11

SKD11 is a high-carbon, high-chromium alloy tool steel that belongs to the cold work die steel category. It is widely used for making precision dies and tools due to its excellent wear resistance, toughness, and hardenability. SKD11 is equivalent to D2 (AISI), X153CrMoV12 (DIN), and 1.2379 (Werkstoff) in other international standards.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.1900 (Tensile Strength) Approx. 1500 (Yield Strength) | Approx. 210-215 | Approx. 10-12 | Annealed: ≤255 HB Quenched & Tempered: ≥60 HRC (Approx. 580-620 HB when converted to Brinell) | 7.85 |

Steel SKH51

SKH51 is a high-speed tool steel that belongs to the M2 grade in the AISI standard. It is widely used in cutting tools due to its excellent wear resistance, high hardness, and good toughness. SKH51 retains its hardness even at elevated temperatures, making it ideal for high-speed

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.2300 (Tensile Strength) Approx.1800 (Yield Strength) | Approx. 210-220 | Approx. 8-10 | Annealed: ≤255 HB Quenched & Tempered: ≥63 HRC (Approx. 620-650 HB when converted to Brinell) | 8.0 |

Steel DC53

DC53 is a high-performance cold work tool steel that is an improved version of SKD11 (D2). It offers superior toughness, wear resistance, and machinability, making it ideal for precision dies, cutting tools, and high-stress mold components. DC53 overcomes the weaknesses of SKD11, such as brittleness and chipping, by modifying its alloy composition and heat treatment properties.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx. 2400 (Tensile Strength)Approx. 2100 (Yield Strength) | Approx. 210-215 | Approx. 12-15 | Annealed: ≤255 HB Quenched & Tempered: ≥62 HRC (Approx. 600-630 HB when converted to Brinell) | 7.85 |

Steel SKS3

SKS3 is a cold work tool steel known for its high toughness, good wear resistance, and excellent machinability. It belongs to the same category as AISI O1 (Oil-Hardening Steel) and DIN 1.2510, making it a widely used material for cutting tools, punches, dies, and knives.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.780-1100 (Tensile Strength)Approx.600-850 (Yield Strength) | Approx. 190-210 | Approx. 10-20 | Annealed: ≤229 HB Quenched & Tempered: ≥55 HRC (Approx. 530-580 HB when converted to Brinell) | 7.7-7.8 |

Steel S136

S136 is a high-purity stainless tool steel developed for plastic mold applications requiring excellent corrosion resistance, polishability, and wear resistance. It is widely used in the medical, optical, and food packaging industries, where high surface quality and durability are critical.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.1350 (Tensile Strength) Approx. 1100(Yield Strength) | Approx. 210 | Approx. 12-15 | Annealed: ≤215 HB Quenched & Tempered: ≥50 HRC (Approx. 480-520 HB when converted to Brinell) | 7.8 |

Steel Stavax

STAVAX is a premium-grade stainless tool steel developed by Böhler-Uddeholm, widely recognized for its exceptional corrosion resistance, polishability, and wear resistance. It is a modified version of AISI 420 tool steel, designed specifically for plastic injection molds and other applications requiring a high-gloss surface finish.

| Tensile Strength, Yield Strength (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm³) |

| Approx.1400 (Tensile Strength) Approx. 1200 (Yield Strength) | Approx. 210 | Approx. 12-15 | Annealed: ≤215 HB Precipitation Hardened: 50-52 HRC (Approx. 480-520 HB when converted to Brinell) | 7.78 |

Why Choose JUNYU CNC Milling Steel Services

At JUNYU, we offer 3-, 4-, and 5-axis CNC milling services, ensuring that even the most complex designs can be machined to high standards with exceptional precision and efficiency. As your reliable manufacturing partner, we are committed to delivering your parts within just a few days after order confirmation—no need to compromise on price, accuracy, or lead time.

Advanced Equipment

We utilize state-of-the-art CNC machining centers for production, and are equipped with CMM (Coordinate Measuring Machines) and high-precision inspection tools to ensure consistent quality in every part we manufacture.

High Cost-Performance Solutions

By using cost-effective materials and implementing full-process cost control, we provide CNC machining services that are both competitively priced and performance-driven.

Diverse Machining Services

In addition to CNC milling, we also offer CNC turning, EDM (Electrical Discharge Machining), WEDM (Wire Electrical Discharge Machining), optical profile grinding, surface finishing, and hardware assembly—providing one-stop solutions for your custom parts manufacturing needs.

Quality and Precision Assurance

We are ISO 9001 certified and can provide material certifications upon request. We support the production of high-precision components with strict tolerance requirements.

Rapid Response and On-Time Delivery

Simply upload your drawings to receive a free online quote. With fast production lead times, we ensure your products are delivered on schedule.

Our CNC machines are capable of executing complex operations such as small-radius cuts and threaded holes while maintaining outstanding accuracy and surface finish.

Features of Custom CNC Milling Steel Parts

Custom CNC milled steel parts typically offer higher strength and structural stability, along with superior machining precision.

Compared to other manufacturing methods, CNC machining enables more efficient production of custom components, significantly reducing lead times.

CNC milling can accurately machine complex geometries, making custom steel parts widely used in industries with strict performance and reliability requirements, such as aerospace, automotive, medical devices, and precision machinery.

Custom parts are non-standard products that cannot be sourced from typical suppliers. They often feature unique functions and structures that standard components cannot provide.

CNC machining shops commonly accept small-batch orders and can ensure both machining quality and on-time delivery according to customer specifications.

These custom CNC steel parts are typically designed and manufactured for specific end-use applications, ensuring optimal performance and compatibility in real-world scenarios.

CNC Milling of Steel – Steel Features and Benefits

The carbon content in steel enhances its strength and fracture resistance. Most types of steel offer good machinability and weldability, and they respond well to heat treatment.

Thanks to its excellent mechanical properties, steel is widely used in industries with high demands for durability and performance, such as automotive and aerospace. In these fields, CNC milling is commonly applied to produce high-precision steel components.

Compared with many other materials, steel not only offers greater strength but also remains cost-effective, making it a practical and reliable choice for a wide range of engineering applications.

What is CNC milling?

CNC milling (Computer Numerical Control milling) is a machining process that uses a computer-controlled milling machine to cut and shape materials. It is widely used for the high-precision manufacturing of parts made from metals, plastics, wood, and other materials.

The most common methods include CNC milling and manual milling. The cutting tools used are called end mills, which feature rotating cylindrical heads with multiple flutes. These tools can move along multiple axes to machine features such as slots, grooves, and external contours.

The equipment used to perform this process is known as a milling machine. In modern manufacturing, CNC milling is typically carried out on computer-controlled machining centers. Whether manual or CNC, milling operations are usually performed in machine shops, and the appropriate method is selected based on the complexity and precision requirements of the part.

Advantages of CNC Milling

Offers excellent adaptability and machining flexibility. Multi-axis CNC milling (such as 3-axis, 4-axis, and 5-axis) can process complex surfaces, internal cavities, undercuts, threaded holes, and other geometries that are difficult to achieve manually.

Capable of machining parts that are difficult or impossible to process using conventional machine tools, including complex curves and three-dimensional surface structures.

Suitable for multi-process machining after a single clamping and positioning, effectively improving machining efficiency and dimensional consistency.

Provides high precision and stable machining quality, meeting the requirements of high-standard manufacturing.

High degree of automation helps reduce operator labor intensity and improves the controllability and efficiency of production management.

Ideal for batch production with strong repeatability: CNC milling ensures consistent dimensions and stable quality for every part in medium to large volume production, meeting the needs of industrial-scale manufacturing.

Compatible with various post-processing techniques: CNC-milled parts can undergo anodizing, electroplating, powder coating, polishing, engraving, and more to meet both functional and aesthetic requirements.

Experience JUNYU Services Now in Just a Few Steps!

Upload your CAD files

Send us your FDF file drawings and CAD or 3D files.

Receive your price

You will receive the quote within a few hours.

Order your parts online

You confirm the order and make the payment through the secure payment platform.

Receive your parts

In a short period of time, the parts you ordered will be delivered directly to your shipping address. You can track your package anytime through your personal account.