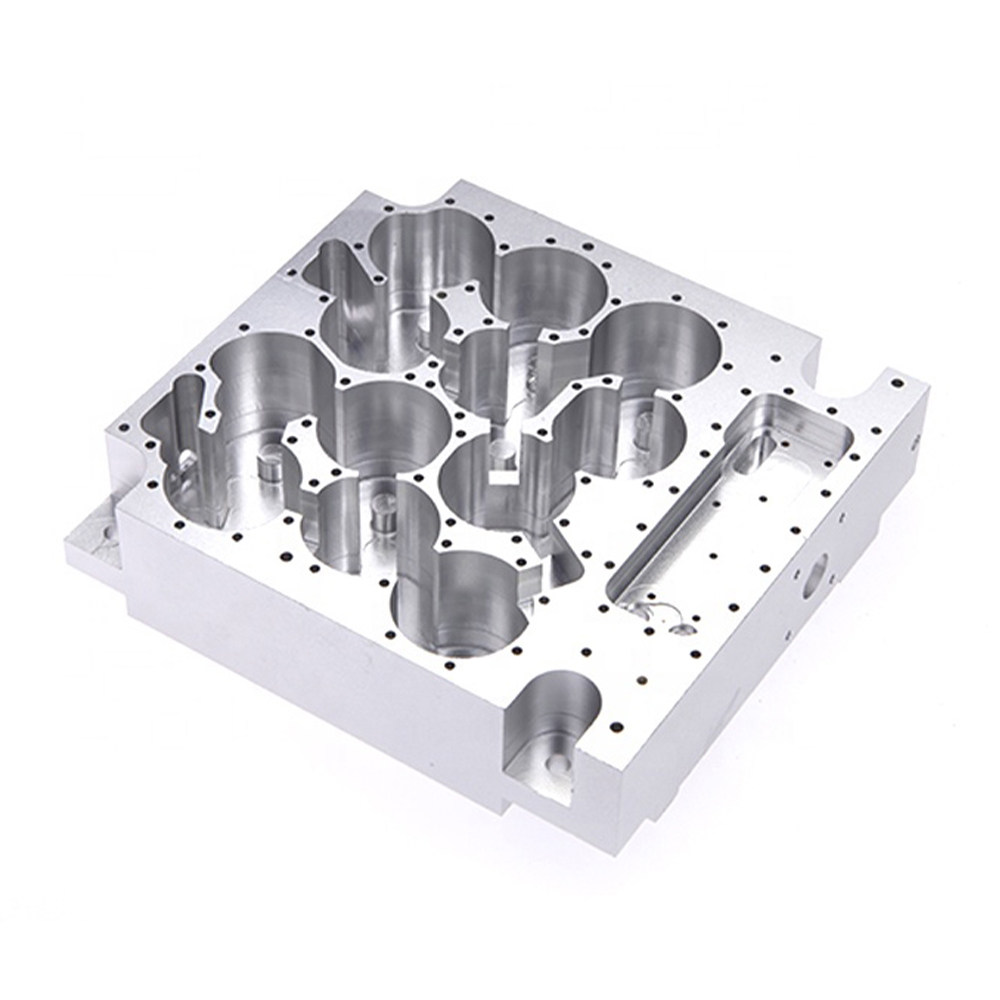

CNC Machined Aluminium parts (Al6061-T6)

- Material: Al6061-T6

- Process: CNC milling

- Tolerance ±0.01

- CNC machining process: on-demand blanking→ CNC rough Machining→ CNC finish machining →CNC drilling→ Deburring and edge treatment→ sandblasting→ and anodized→ Cleaning and Packaging

- Surface Treatment: sandblasting + natural color conductive anodized

- Features: The inner cavity is thin-walled, and the flatness in the length direction is required to be 0.03. No scratch allowed on the surface.

Capabilities of CNC Milling for 6061-T6 Aluminum Parts

- Raw material – 6061-T6 aluminum alloy plate

- Equipment – 3-axis or 5-axis CNC milling machine

- Cutting tools – Milling cutters, drills, taps, precision reamers, etc.

- Machining process – on-demand blanking→ CNC rough Machining→ CNC finish machining → Deburring and edge treatment

- Inspection tools & equipment – Coordinate Measuring Machine, digital display vernier caliper, threaded plug gauge

- Surface finishing treatment – Sandblasting followed by conductive natural color anodizing, film thickness 20μm

- Packing – 5-layer corrugated paper outer box + bubble bag + pearl sponge

Definition of CNC Milling

CNC milling (also known as Computer Numerical Control milling) is a precision machining process in which a computer controlled spindle drives a rotating cutting tool to remove excess material from a workpiece, producing custom designed parts or products.

This technique is applicable to a wide range of materials—including steel, tungsten carbide, and various plastics—and enables the on demand manufacture of bespoke components. Our precision CNC services center on mechanical machining and encompass high accuracy processes such as turning, milling, and grinding to satisfy stringent dimensional requirements.

By automating complex tool movements through programmable instructions, CNC milling delivers reliable, high quality results across all levels of part complexity and material types, making it a cornerstone of modern manufacturing.

Definition of Aluminum 6061-T6

Aluminum 6061 T6 denotes a 6000 series alloy whose principal alloying elements are aluminum, magnesium, and silicon. Its T6 temper is achieved through three sequential processes: solution heat treatment, quenching, and artificial aging.

Heat-Treatment Process

- Solution Treatment: Heat the alloy to 520–540 °C and hold for about 1 hour to fully dissolve the strengthening phases (Mg and Si) into the aluminum matrix. Immediately quench—typically in water—to form a supersaturated solid solution.

- Aging Treatment:

- Natural Aging: After quenching, allow the material to rest at room temperature for several days, during which strength increases gradually as Mg₂Si precipitates form.

- Artificial Aging: Reheat to 150–200 °C and hold for 6–12 hours (or 1–18 hours, depending on part size, geometry, and performance requirements) to accelerate Mg₂Si precipitation and significantly enhance strength.

Key Advantages of 6061 T6

- Excellent strength to weight ratio

- Outstanding resistance to atmospheric corrosion

- Good machinability and weldability (with proper post weld aging)

- Superior fatigue performance

Typical Applications

- Structural frames and supports (automotive, aerospace)

- Bicycle frames and sporting equipment

- Marine fittings and hardware

- Precision-machined fittings, valves, and extruded profiles

Thanks to its balanced mechanical properties and corrosion resistance, 6061 T6 remains one of the most widely used aluminum alloys for general structural and engineering applications.