CNC Machining Aluminum Parts

Aluminum alloy precision parts and products are highly favored for their lightweight and exquisite appearance, widely used in both industrial and everyday applications. Especially in recent years, with the continuous advancement of technology and societal development, people’s demand for product diversification has been increasing. As a result, the more advanced the processing technology of aluminum alloy products, the greater the market demand, the higher their popularity, and the larger the profit potential. CNC machining is one of the ideal methods for processing aluminum alloy shell products.

Advantage of aluminum in CNC machining.

1.Wide Applications

2.Low Density and High Strength

3.Variety of Quality Aluminum Materials

4.Good Electrical Conductivity

5.Cost-effective Production Methods

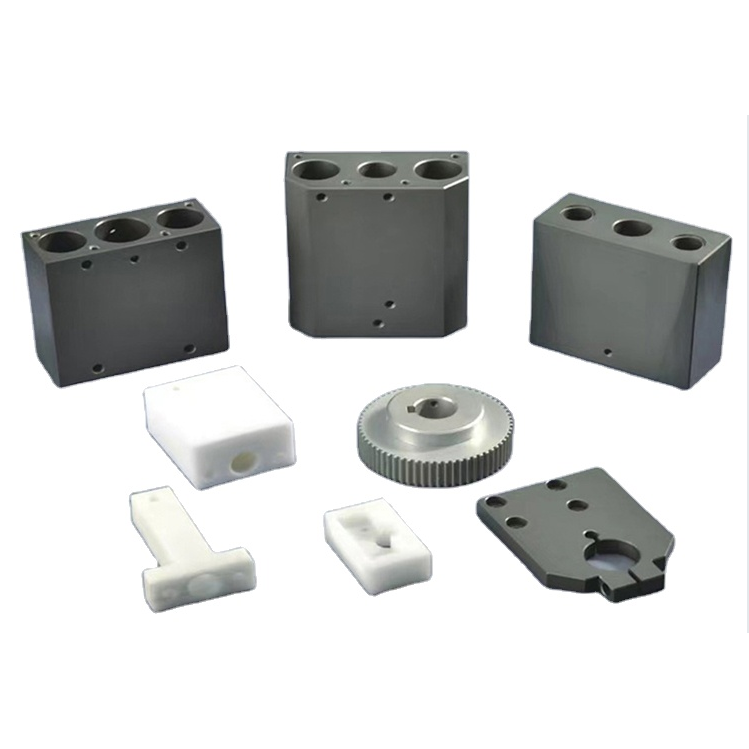

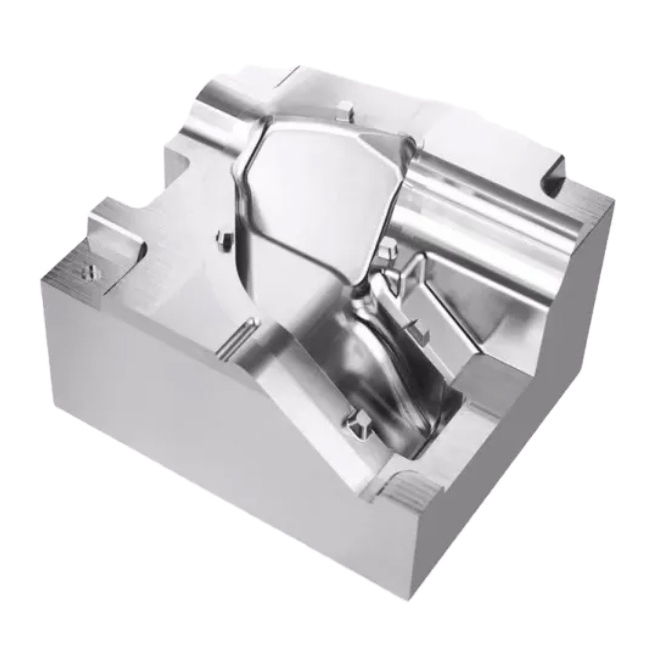

JUNYU CNC Machining Aluminum Parts

JUNYU’s capability of CNC Machining Aluminum parts

| Processes | Lead Time | Tolerance | Price | Applications | Alloys | Finishing Options |

| CNC Machining | As fast as 3 days | With drawing: Precision up to +/- 0.005 mm. No drawing: ISO 2768 medium | Fees are based on the product. | Lightweight and cost-effective, CNC Lathe suitable for prototyping to mass production. | 6061, 7075, 7050, 2024, 5052, 6063, MIC6 | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

CNC Machining Materials for Aluminum Parts

Aluminum 2024

2024 aluminum alloy is commonly used in aerospace, military, and other applications that require high strength and good corrosion resistance. It is enhanced with alloying elements such as copper, magnesium, and manganese to improve its mechanical properties. Although 2024 aluminum alloy is not as strong as 7075 aluminum, it is often selected when a high strength-to-weight ratio is required. 2024 aluminum alloy is heat treatable and non-magnetic.

| Density(p) | Electrical Conductivity | Young’s Modulus (E) | Elongation (ε) at break |

| 2.78 g/cm3 (0.1Ib/in²) | 30% | 73 GPa (10.6Msi) | 10-25% |

Aluminum 6061

The most commonly used aluminum alloy in our machining services is Aluminum 6061, a versatile and easy-to-machine metal. It offers excellent corrosion resistance, is non-magnetic, and can be heat treated.

| Tensile Strength,Yield (MPa) | Young’s Modulus (E) | Density(p) | Specific Heat Capacity (c) | Elongation (ε) at break |

| 124-290 MPa (18.0-42.1 ksi) | 68GPa (9,900 ksi) | 2.70 g/cm² | 897 J/(kg-K) | 12-25% |

Aluminum 6063

AA6063 aluminum is a common aluminum alloy, with magnesium and silicon as the primary alloying elements. Compared to 6061 aluminum, 6063 aluminum offers better corrosion resistance and formability. It is not suitable for high-strength applications but can be used for exterior railings and decorative trim. The advantage of CNC machined 6063 aluminum is that it is heat treatable and non-magnetic.

| Density(p) | Young’s modulus (E) | Tensile Strength (ot) | Elongation (ε) at break | Specific Heat Capacity (c) |

| 2.69 g/cm3 | 68.3 GPa (9,910 ksi) | 145-186 MPa (21.0-27.0 ksi) | 18-33% | 900 J/kg*K |

Aluminum 5052

5052 aluminum alloy is relatively easy to weld, with magnesium as the primary alloying element. It is easy to form, heat treatable, and non-magnetic. It has excellent corrosion resistance, especially in seawater and salt spray environments, making it the material of choice for applications with high corrosion resistance requirements in marine engineering (such as LNG tanker tanks). Its resistance to saltwater and salt spray allows it to withstand the challenges of marine environments, which is why it is widely used in marine, shipbuilding, and related industries.

Typical applications of 5052 aluminum alloy include marine, aerospace, construction, general sheet metal work, heat exchangers, fuel pipelines and tanks, flooring panels, streetlights, appliances, rivets, and wire.

| Density (p) | Volume Resis tivity(p) | Young’s Modulus (E) | Elongation (e) at break | Tensile Strength,Yield (MPa) |

| 2.68 g/cm3 | 49.3-49.9 nOhm*m | 69.3 GPa | 7-27% | 195-290 MPa (28.3—42.1 ksi) |

Aluminum 7075

7075 aluminum alloy is typically a high-strength, high-hardness alternative to 6061 aluminum alloy. It is widely used for parts in high-stress environments. Compared to 6061 aluminum, 7075 aluminum has slightly lower corrosion resistance. However, 7075 aluminum is non-magnetic and can be heat treated.

| Density (p) | Young’s modulus (E) | Tensile Strength (ot) | Elongation (ε) at break | Maximum Yield Strength |

| 2.81 g/cc (0.102 Ib/cu in) | 71.7 GPa (10,400 ksi) | 572 MPa (83.0 ksi) | 11% | 280 MPa (41 ksi) |

Post-processing of CNC machined aluminum parts

Untreated aluminum typically has a matte silver or gray surface, depending on the roughness of the surface.

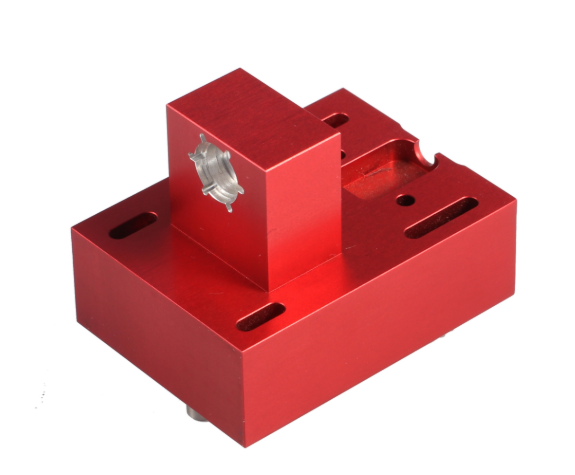

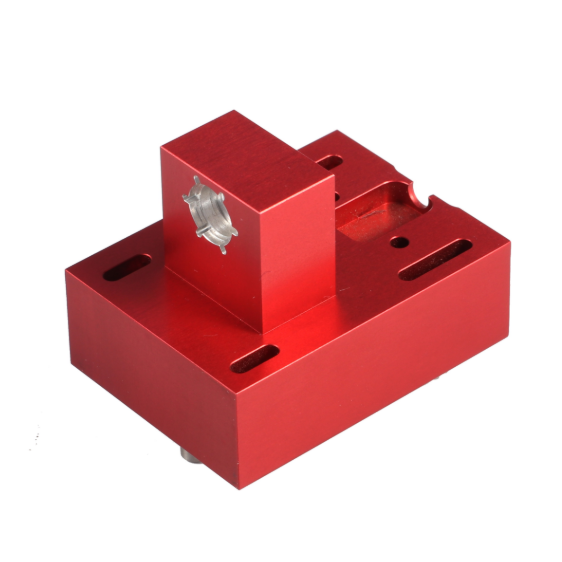

Many aluminum consumer products, such as laptops, require anodizing. Anodizing not only offers various color options but also provides a consistent sheen across the part.

Aluminum can also be treated with media blasting, sanding, and hand polishing to achieve various surface finishes.

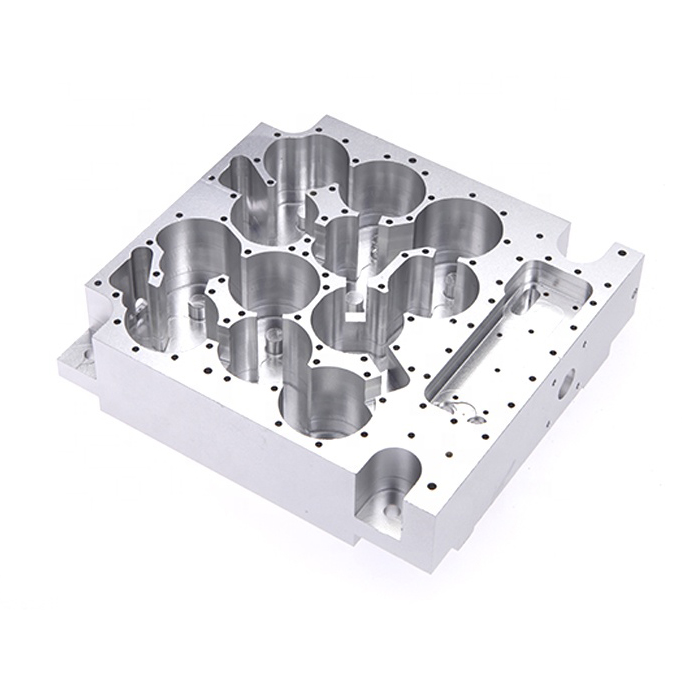

CNC Machining Services for Aluminum Parts – Aluminum Parts Machining in China

In order to meet the demand for diversity and high quality in aluminum alloy shell products, it is essential to summarize processing techniques during the manufacturing process. Based on years of CNC machining experience, JUNYU has summarized the key machining techniques to be considered when processing aluminum alloy shells. JUNYU is a highly professional CNC machining company in China, offering precise CNC aluminum parts machining services. Our machining equipment includes three-axis, four-axis, and five-axis machining centers, drilling and tapping centers, CNC lathes, and over 100 conventional machine tools such as lathes, milling machines, drilling machines, and grinders.

Advantages of Our Machining Services

1.With over ten years of CNC machining experience, we are able to provide comprehensive solutions to solve various problems.

2.ring the CNC milling of aluminum parts, we conduct strict comprehensive and routine inspections to ensure product quality.

3.We have a strong professional technical team and an efficient management system, equipped with advanced manufacturing equipment to ensure the best CNC aluminum parts machining service for you.