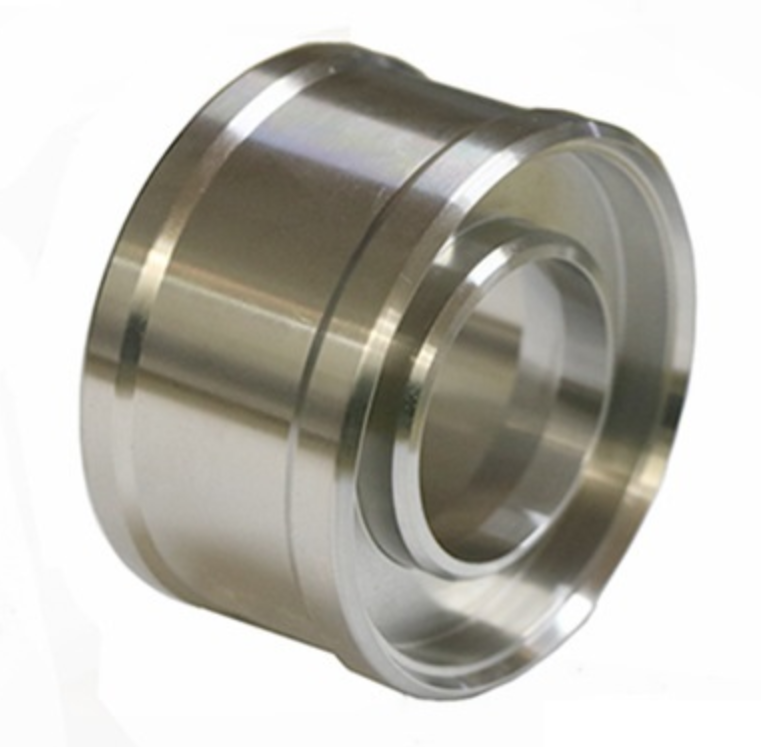

CNC Turning Stainless Steel Parts

Stainless steel is a metal known for its strong corrosion resistance and excellent mechanical properties. It is widely used across various industries and is an ideal material for milling. There are many types of stainless steel, and to mill all of them effectively, a high-end CNC system is required. This technology is applicable in industries such as automotive, mold-making, shipbuilding, aerospace, and engineering machinery. CNC stainless steel milling is considered the best solution by many industries that require stainless steel parts due to its high precision, efficiency, and cost-effectiveness.

The leading CNC machining expert In stainless steel

JUNYU is one of the most advanced CNC technology companies in China, with over 10 years of experience in CNC machining. We have a team of skilled operators and numerous technicians, forming a strong technical force to provide you with the most professional technical services. Equipped with 70 state-of-the-art CNC milling centers, including 3-axis and 5-axis milling machines, and supported by a professional engineering team, we are well-prepared to handle a variety of challenges. We offer a wide range of stainless steel processing services to meet the diverse needs of our customers.

Advantages of using stainless steel in CNC turning

· Excellent Corrosion Resistance

Stainless steel naturally resists rust and chemical corrosion, making it ideal for components used in harsh environments such as marine, chemical, or medical applications.

· High Strength and Toughness

It offers superior mechanical properties, including high tensile strength and impact resistance, allowing the production of durable parts that can withstand mechanical stress and wear.

· Temperature Resistance

Stainless steel maintains its structural integrity and performance under both high and low temperature conditions, making it suitable for aerospace, automotive, and industrial applications.

· Good Surface Finish

It supports excellent surface finishes after machining, reducing the need for secondary polishing or surface treatment in many cases.

· Material Stability and Dimensional Accuracy

Stainless steel’s thermal and mechanical stability contributes to excellent dimensional control during CNC turning, especially for high-precision components.

· Biocompatibility

Certain stainless steel grades (e.g., 316L) are biocompatible, making them suitable for medical instruments and implants.

· Wide Range of Alloys Available

Multiple stainless steel grades are available to suit different application needs, such as 303 for machinability, 304 for general use, or 316 for high corrosion resistance.

Why Stainless Steel Is Hard to Turn

- Work Hardening Tendency

Stainless steel tends to harden quickly during machining. If the cutting parameters are not optimized, the surface becomes harder as it’s being cut, leading to tool wear and reduced machinability. - High Toughness

Its high ductility and toughness make chip breaking more difficult, which can lead to long, continuous chips that interfere with machining efficiency and safety. - Low Thermal Conductivity

Stainless steel does not dissipate heat well, which causes heat to concentrate at the cutting edge, accelerating tool wear and potentially damaging the workpiece surface. - Abrasiveness

The alloying elements in stainless steel (such as chromium and molybdenum) make it more abrasive, which shortens tool life unless appropriate tooling is used.

How to Overcome These Challenges

- Use sharp, wear-resistant cutting tools (e.g., coated carbide inserts)

- Apply proper cutting speeds and feed rates

- Use copious cutting fluid to control heat and improve surface finish

- Opt for positive rake angles and optimized chip breakers

- Use rigid fixturing to minimize vibration and tool deflection