Metal Stamping Mold Accessories

| Name | Metal Stamping mold Accessories |

| Material | SKD11 |

| Hardness | HRC 60-62 |

| Specification | Non-standard/Custom |

| Custom | OEM/ODM |

| Surface treatment | None |

| surface finish | Ra0.15-Ra0.3um |

| Tolerance | ±0.002mm |

| Mold Type | Stamping mold |

| Wire Diameter | 0.03mm-0.2mm |

| MOQ | 1PCS |

| CNC Machining or Not | CNC Machining |

| Sample | Available |

| Place of Origin | Dongguan GuangDong China |

| Supply Ability | 20000 Pieces Per Month |

| Material Capabilities | 1.2343,1.2083,1.2842,C45(K1045),C2100,C46(K1046),C20,SKD11,SKD61,SKH51,1.2379,k390,ELMAX,SKS3,S45C,S290,HPM31,SLD,YXM1,HAP40,YXR33,HPM38,D2.stavax,S-7,NA20,RD50,RD30,WF30,KG7,WF15,CF-H40S,CF-H25S,SUJ2,etc. |

| Packaging&Delivery Packaging Details | PP bag,carton ,box or according to customer’s requirements |

| Port | GUANGZHOU |

| Lead Time :Quantity(pieces)1-5000 | 3-7days |

| Lead Time :>50000 | TO be negotiated |

| Shipping | Shipped by a convenient and cost-effective way |

Process: on-demand blanking → milling→ heat treatment→ grinding→ WEDM→Deburring and edge treatment→ Cleaning and Packaging

Product parameters

Perpendicularity

0.002MM

Parallelism

0.001MM

Roughness

EDM Roughness: Ra0.4-Ra0.8um

Roughness

Grinding Roughness: Ra0.15-Ra0.2um

Roughness

Wire-Cut Roughness: Ra0.15-Ra0.3um

Product Overview

These precision wire-cut parts are used in motor molds. It features a stable machining tolerance within ±0.002 mm, with geometric tolerances (perpendicularity of 0.002 mm and parallelism of 0.001 mm),The minimum internal radius (R) of this workpiece is R0.15, which is machined using a wire with a diameter of φ0.2 mm. Widely used in high-precision mold manufacturing, aerospace, electronic components, and medical device industries, precision wire-cut parts serve as key components for applications such as fine cavities of molds, precision structures of aerospace parts, and micro-components of medical equipment. They provide critical support for ensuring the performance stability of high-end products across various industries.

Why Choose Us

- Over 15 Years of Expertise – Trusted by clients across Japan, Germany, Singapore, Malaysia, and Thailand.

- Direct Factory Advantage – Competitive pricing without unnecessary markups.

- Complimentary Support – Free engineering advice and samples before mass production.

- Guaranteed Precision – Every part is inspected with CMM reports for accuracy.

- On-Time Delivery – Flexible lead times from 7 to 20 days to meet your schedule.

- High Precision– ±0.002mm tolerance

- Lead Time- 7-20 days

- QC Assurance -100% inspection before delivery

precision wire-cut parts are used in these fields: Stamping dies, die casting molds, plastic molds, precision transmission parts, guide & positioning components, structural & functional parts, precision instrument parts, semiconductor equipment, electronic connectors & terminals, surgical tools, medical equipment parts

Our Exhibition Display Diagram

2015 Japan Exhibition

2018 Japan Exhibition

2019 Japan Exhibition

2019 German Exhibition

2023 Japan Exhibition

Our WEDM workshop

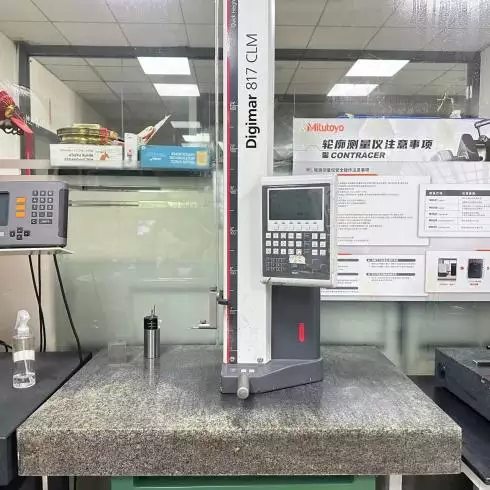

Our Quality Control Department

Looking for a precision wire-cut parts manufacturer in China?

We provide custom wire EDM solutions with high accuracy and reliable lead times for global B2B buyers.

Contact us today to get a free design review, quotation, and sample for your next project.

Email: info@junyudg.com

WhatsApp: +86 13602364710