What is metal stamping mold making?

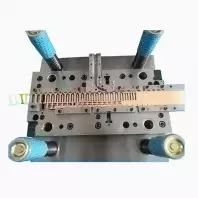

Metal stamping mold making refers to the process of designing and manufacturing the dies (tools) used in metal stamping. These molds are essential for shaping, cutting, bending, or forming sheet metal into precise components using a stamping press.

The Process Includes:

- Design

Engineers use CAD software to create 2D/3D models of the mold, considering part shape, tolerances, blanking layout, and press type. - Material Selection

Tool steel (like SKD11, DC53, D2) or carbide is selected based on part material, quantity, and wear resistance needs. - Machining

The mold components are fabricated using CNC machining, wire cutting (WEDM), EDM, surface grinding, and sometimes heat treatment. - Assembly

After precision machining, upper and lower die plates, punches, dies, stripper plates, and guide pins are assembled. - Trial and Debugging

The mold is tested on a stamping press to verify forming accuracy and ensure it meets production specifications. Fine-tuning may be needed to optimize performance.

Application Areas:

- Automotive: body panels, brackets, clips

- Electronics: connector pins, shielding parts

- Appliances: enclosures, frames

- Hardware: tools, fasteners

Why It Matters:

Metal stamping molds are critical for high-speed, high-precision, and low-cost mass production of metal parts. A well-designed stamping mold ensures dimensional consistency, extended mold life, and stable quality across large production volumes.

What is a Metal Stamping Mold?

A metal stamping mold (also called a stamping die) is a precision tool used in the metal stamping process to form sheet metal into desired shapes through cutting, bending, punching, or forming. It is installed on a stamping press, which applies high pressure to deform the metal sheet according to the mold’s design.

Key Features:

- Custom-made tool designed to match the geometry of the final part.

- Made from high-strength materials like tool steel (e.g., SKD11, DC53) for durability and wear resistance.

- Can perform single or multiple operations in one stroke (e.g., blanking, piercing, bending, drawing).

Basic Components:

- Punch – Moves downward and deforms the material.

- Die (Cavity) – Supports the material and defines the final shape.

- Stripper Plate – Removes the workpiece from the punch after stamping.

- Guide Pins – Ensure precise alignment between punch and die.

Common Applications:

- Automotive: brackets, frames, clips

- Electronics: terminals, connectors

- Household Appliances: structural panels, enclosures

- Industrial Hardware: washers, hinges, fasteners

Why It Matters:

Metal stamping molds are essential for mass-producing metal parts with high accuracy, efficiency, and cost control. They enable the creation of consistent, complex parts at high production speeds.

Common Materials for Metal Stamping Mold

Choosing the right mold material is critical to ensuring mold life, wear resistance, and machining accuracy. Below are some of the commonly used materials in metal stamping molds along with their characteristics.

| Material | Common Grades | Key Features | Typical Uses |

| Cold Work Tool Steel | SKD11, D2, Cr12MoV | High hardness, wear resistance, suitable for cold forming | Punches, dies for blanking, piercing |

| High Toughness Tool Steel | DC53, SKD61 | Improved toughness and wear resistance, crack resistance | Progressive dies, bending & forming |

| Carbide | Tungsten Carbide (e.g., YG15) | Extremely high hardness and wear resistance, long tool life | High-volume blanking, precision punches |

| High-Speed Steel | M2, M42 | Good toughness, heat resistance, and edge retention | Complex forming tools, fine punches |

| Pre-hardened Steel | P20, 718 | Good machinability, moderate hardness, no post-heat treatment | Base plates, mold holders |

| Alloy Tool Steel | H13, 1.2344 (hot work steel) | Good thermal fatigue resistance, used when heat is involved | Warm forming molds, hybrid operations |

Material Selection Tips:

- For high wear conditions, use SKD11 or Carbide.

- For complex forming or bending, DC53 offers better toughness.

- For cost-effective tooling, P20 or 718 is suitable for non-critical parts.

- For high-volume stamping, Carbide ensures long-term dimensional stability.

Metal Stamping Mold Materials & Their Suitable Applications

| Material | Suitable Applications | Key Features |

| SKD11 / D2 | Precision blanking, punching, and trimming dies for carbon steel and stainless steel | High hardness, excellent wear resistance, good dimensional stability |

| DC53 | High-strength forming, bending, and compound dies for complex shapes | Superior toughness over SKD11, crack resistance, high wear resistance |

| Carbide | High-volume blanking, fine punching (e.g., motor laminations, silicon steel) | Ultra-high hardness and wear resistance, ideal for long-life molds |

| M2 / M42 (HSS) | Micro punches, intricate and small punching dies | Sharp cutting edge, excellent heat resistance, suitable for continuous stamping |

| P20 / 718 | Mold bases, backing plates, and non-forming components | Good machinability, cost-effective, no heat treatment required |

| SKD61 / H13 | Warm forming molds or light-duty hot stamping applications | Great thermal fatigue resistance and toughness, used in thermal operations |

| Cr12MoV / 1.2379 | Blanking and punching under moderate load conditions | Strong wear resistance, minimal heat treatment deformation, cost-effective |

Material Selection Tips:

- For high wear conditions, choose SKD11 or Carbide.

- For complex shapes or high toughness demands, DC53 is recommended.

- For long-life and high-speed stamping, use Carbide or HSS (M2/M42).

- For non-working mold components, P20 or 718 provides an economical solution.

- For warm or thermal stamping, SKD61 or H13 is ideal.

Classification of Metal Stamping Molds

Metal stamping molds can be classified based on their function, structure, and guiding method. Below is an overview of the common types:

1. By Stamping Function

| Mold Type | Description |

| Blanking Die | Cuts flat sheet metal into a specific external shape or profile. |

| Piercing Die | Punches holes or cutouts in the sheet metal. |

| Bending Die | Bends the sheet metal along straight or curved lines. |

| Drawing Die | Forms flat metal sheets into hollow or deep-drawn parts. |

| Forming Die | Performs additional shaping, flattening, or edge finishing to refine the part. |

| Trimming Die | Trims excess material from deep-drawn or formed parts. |

| Compound Die | Combines multiple operations (e.g., blanking + piercing) in a single stroke. |

| Progressive Die | Performs a series of stamping operations in multiple stations with each press stroke, as the strip material advances through the die. |

2. By Structural Form

| Mold Type | Description |

| Single-operation Die | Performs only one operation per press stroke; simple structure. |

| Compound/Multiple Die | Performs multiple operations in one stroke; improves efficiency. |

| Progressive Die | Multi-stage mold; the material moves station by station to complete various operations continuously. |

| Transfer Die | The workpiece is transferred between stations using mechanical arms; ideal for large and complex parts. |

3. By Guiding Method

| Mold Type | Description |

| Unguided Die | No built-in guiding system; relies on press alignment. |

| Guided Die | Uses guide posts and bushings for precise alignment between upper and lower die halves; ensures higher accuracy. |

Summary

Each type of stamping mold serves different production needs.

- Progressive dies are ideal for high-volume, high-efficiency manufacturing.

- Compound dies save space and consolidate multiple operations into one stroke.

- Drawing dies are used for deep-formed components like cups, shells, or containers.