CNC Milling Service

JUNYU offers high-quality CNC milling services, supporting custom part machining in a wide range of specifications and materials. Whether it’s a simple straight-line structure or a complex geometric shape, we can quickly turn your designs into reality and ensure fast, reliable delivery.

CNC milling is a highly efficient CNC machining process that removes excess material from a solid block using multi-axis rotary cutting tools. Whether working with plastic or metal, simple structures or complex geometries, CNC milling can provide precise and reliable custom solutions for a wide range of parts.

JUNYU is equipped with advanced 3-axis, 4-axis, and 5-axis high-precision CNC milling centers, supported by an experienced technical team. We can quickly realize designs from simple straight lines to intricate shapes and deliver them efficiently, helping your team focus on product launch and market expansion.

If you are looking for a trustworthy CNC milling partner, JUNYU is undoubtedly your best choice!

Our CNC Milling Capabilities

Fast Machining

High-precision parts can be produced in as fast as 1 day.

Quality Assurance

We are ISO9001:2008 and TS16949 certified, ensuring the consistent high quality of our products.

Short Delivery Time

We ensure that our products are delivered to your door as quickly as possible.

We have a team of experienced engineers who can precisely develop machining solutions based on your drawings, select the most suitable tools, and efficiently complete high-quality milling operations. We ensure excellent surface finishes, strict dimensional tolerances, and outstanding overall part quality.

JUNYU is committed to providing customers with comprehensive, customized CNC milling solutions to support the efficient progress of your projects.

If you encounter any challenges during the CNC machining process, feel free to contact us. JUNYU will provide you with professional, efficient, and reliable services to help you overcome them with ease.

Available Materials for CNC Milling

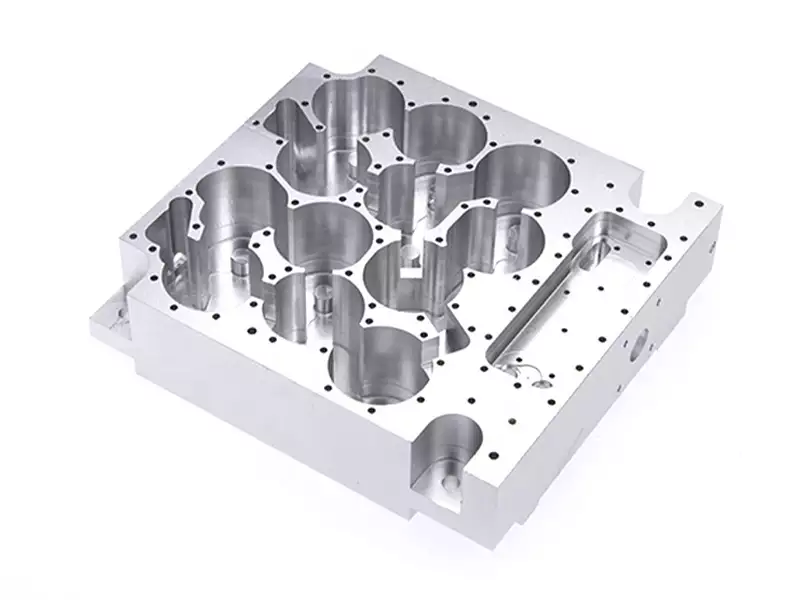

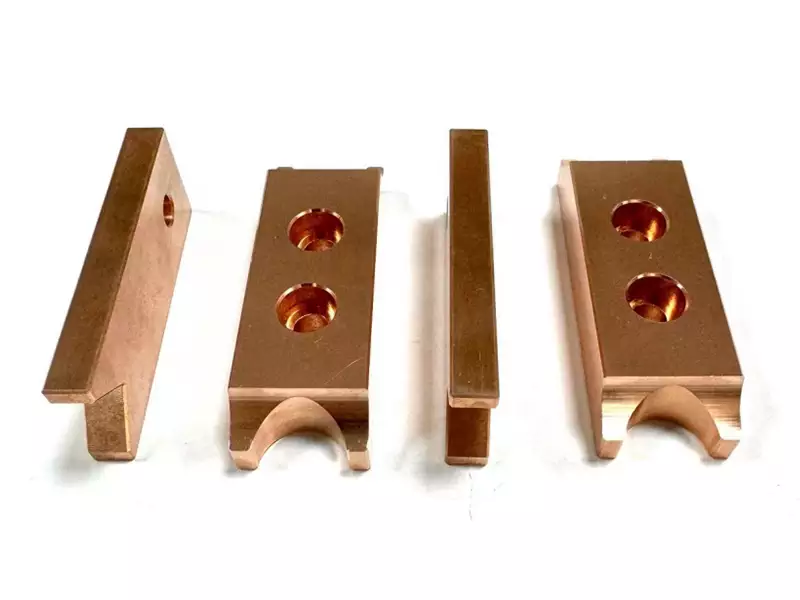

CNC Milling Products

Surface Finishes for CNC Milling

Aluminum

Anodizing, Bead blasting, Powder Coating, Electroplating, Polishing, Brushing,

Other metals

PVD coating, Bead blasting, Powder Coating, Electroplating, Polishing, Brushing

Steel

R-coating , DLC-S, hydrogen-free DLC Bead blasting, Powder Coating, Electroplating, Polishing, Brushing

Process Specification Requirements

| MAX. Part Diameter | Metal components | Plastic components |

| 3-axis | 1500mm(59.055″) | 1500mm(59.055″) |

| 4-axis | 350mm(13.779″) | 350mm(13.779″) |

| 5-axis | 500mm(19.685″) | 500mm(19.685″) |

| MIN. Part Diameter | Metal components | Plastic components |

| 3-axis | 0.3mm | 0.3mm |

| 4-axis | 0.3mm | 0.3mm |

| 5-axis | 0.3mm | 0.3mm |

Lowest CNC Service Price

Four Key Advantages Behind Our Competitive Pricing

1. Advanced and Efficient Machining Equipment

We are equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers. High-speed, high-precision equipment significantly improves machining efficiency, shortens production cycles, and effectively reduces the unit cost.

2. Refined and Optimized Production Processes

With years of industry experience, we continuously optimize our production processes, minimizing material waste and setup time, enhancing overall operational efficiency, and reducing manufacturing costs.

3. Professional Engineering and Technical Team

Our engineers develop optimal machining strategies based on project requirements, selecting the most suitable tools and planning efficient machining paths to improve productivity, reduce errors, and control costs at the source.

4. Stable and Reliable Supply Chain System

We maintain long-term partnerships with premium material suppliers and logistics providers, ensuring low-cost procurement of high-quality raw materials and efficient delivery, further reducing overall production costs.

If you are looking for a low CNC service price, please do not hesitate to get a quote!

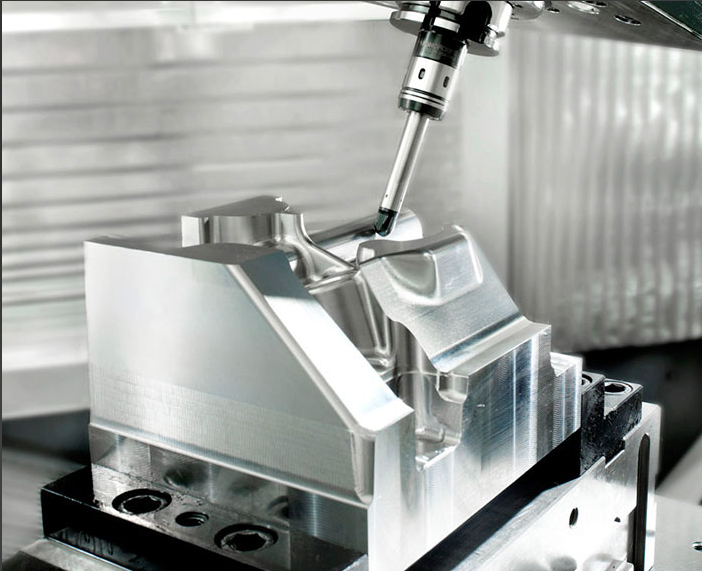

Our CNC Machining Center

CNC Milling Tolerances

± 0.005mm(metal) / ±0.05mm(plastic)

Why Choose JUNYU for CNC Milling?

Advanced Equipment: Equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers to handle a wide range of complex requirements with precision and speed.

Professional Team: Our experienced engineers and technicians ensure optimal machining strategies, precise operations, and strict quality control.

Fast Lead Time At JUNYU Machine, we utilize the latest CNC technology to produce high-precision and fast-milling parts. With optimized processes, we can complete production in as little as one day, offering our customers exceptionally short lead times to accelerate their project schedules.

Guaranteed Quality We offer a full range of customized CNC milling services to meet diverse project needs. Our experienced engineers design optimal milling processes and select the most suitable tools based on your drawings, ensuring both high efficiency and excellent surface quality. By maintaining strict tolerances, we guarantee superior product quality.

Cost Efficiency With over 70 advanced CNC machining centers and a highly collaborative professional team, we significantly reduce production time and labor costs, achieving extremely competitive pricing. Additionally, we can offer value-added services such as free parts assembly, tailored to your specific requirements.

Wide Material and Surface Finishing Options CNC milling not only saves time but also supports a wide range of materials — from various plastics to metal blocks of different specifications. CNC milled parts can be finished with multiple surface treatments, including painting, anodizing, and chrome plating, delivering the perfect combination of functionality and versatility.

Capability for Complex Parts Thanks to multi-axis machining capabilities, our milling tools can approach workpieces from multiple angles, making it possible to produce parts with highly complex geometries. The more axes involved, the more intricate the parts that can be manufactured. If your CNC project requires irregular or complex shapes, CNC milling is the ideal solution.

Overview of CNC Milling

What is CNC Milling?

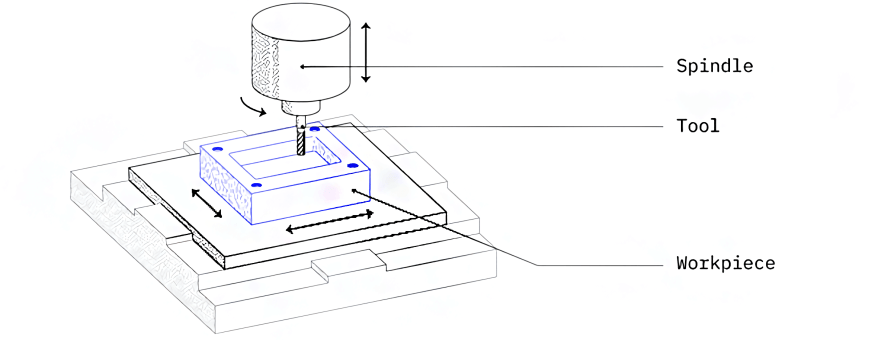

CNC milling is a high-precision, high-efficiency machining process that uses a multi-axis CNC system to control rotary cutting tools, removing excess material from a solid block along a pre-programmed path to create complex parts.

This process is suitable for machining a wide range of materials, including metals and plastics, and supports the production of everything from simple contours to intricate geometries.

With its outstanding precision, flexibility, and high repeatability, CNC milling has been widely adopted across industries such as aerospace, automotive, medical, and electronics, becoming one of the essential methods in modern manufacturing.

How Does CNC Milling Work?

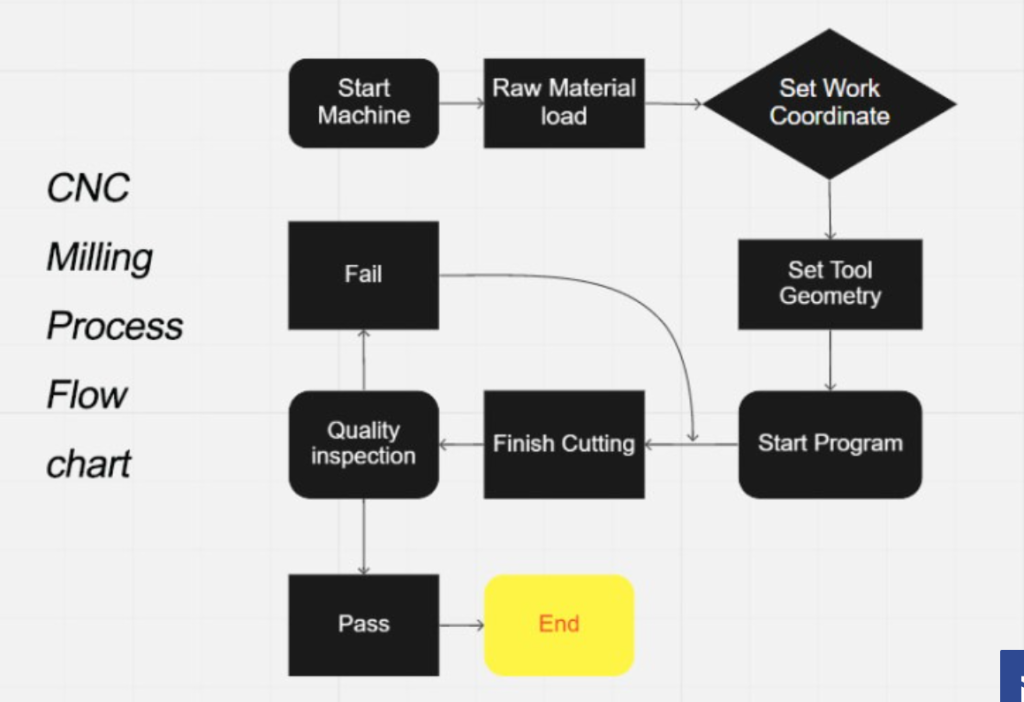

The CNC milling process begins with designers creating a digital part model using CAD (Computer-Aided Design) software. The file is then converted into “G-code,” allowing the CNC milling machine to read and execute machining instructions.

A CNC milling machine is equipped with a worktable and workpiece fixtures to securely hold a solid block of raw material (the “workpiece”) in place. Depending on the machine configuration, the worktable can either be stationary or movable.

During machining, a high-speed rotating cutting tool moves according to the G-code instructions, contacting the workpiece and gradually removing excess material until the part is fully formed. Some milling machines utilize a moving worktable to achieve additional cutting angles, enhancing machining flexibility and complexity.

CNC milling machines are capable of efficiently cutting a wide range of hard metal materials, offering greater cutting capabilities than traditional 3-axis equipment. They are particularly suitable for manufacturing complex and high-precision components.

It is important to note that CNC milling differs from CNC turning. In CNC turning, it is the workpiece that rotates, rather than the cutting tool.

Different Types of CNC Milling

CNC milling machines are typically categorized by the number of axes. The more axes they have, the more ways the tools and workpieces can move, increasing cutting flexibility and enabling the production of more complex parts in less time.

- Vertical CNC Milling:In vertical CNC milling, the spindle (which holds the cutting tool) is oriented vertically. The workpiece is typically fixed to a table and moves in the X, Y, and Z axes.

- Horizontal CNC Milling:Here, the spindle is positioned horizontally, meaning that the cutting tool spins horizontally as well. The workpiece is often mounted on a horizontal table.

- 5-Axis CNC Milling:5-axis CNC milling refers to the ability of the machine to move a part or tool across five different axes. This means it can rotate in both the X, Y, and Z axes, as well as rotate on two additional axes.

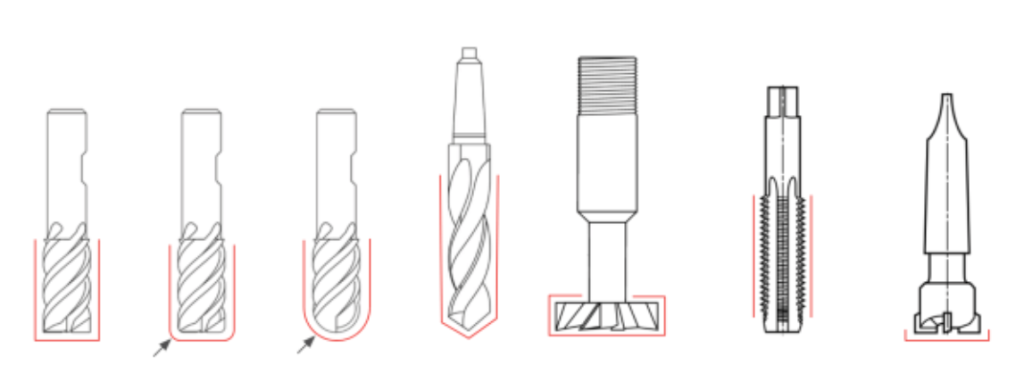

CNC Milling Tools

CNC milling machines can be equipped with different knives/tools to achieve different types of cutting. These tools include end mill, face mill, slab mill, fly cutter, ball nose cutter, hollow cutter, roughing end mill, drill, tap, boring tool, finishing tools, chamfer mill ,radius cutter, engraving tools ,thread mill, etc.

Try Junyu Out Now In Just A Few Steps

Upload your 2D/3D files

Choose the process

Order your parts online

Receive your parts