CNC Drilling Service

CNC drilling can precisely create holes or cut threads on various material surfaces. It uses computer-automated machines to drill precision holes or threads into surfaces made of metals, hard plastics, wood, and most other rigid materials. We offer CNC drilling services for customization and modification of boats, shoe lasts, golf clubs, furniture, and more.

At JUNYU, we also provide a variety of other CNC services, including CNC milling, CNC turning, and more. With our professional design team, JUNYU can help you quickly create the perfect drilling plan. Contact us now and provide your CAD files to get started with your project!

Our CNC Drilling Capability

High Precision CNC Drilling

We utilize the most advanced equipment to deliver parts with the precise accuracy our customers require.

Varieties of Drilling Parts

We accept orders for a wide range of parts, tailored to your specific material and shape.

Requirements

We provide CNC drilling services, ensuring quick delivery of your products.

How Does CNC Drilling Work

In the CNC drilling process, the workpiece remains stationary, while the cutting tool moves to align with the hole center and rotates to drill the desired hole. CNC drilling is primarily carried out using CNC milling machines and lathes. The round holes produced by CNC drilling services are typically used for screws and bolts. CNC drilling can be applied to a variety of materials, including metals, wood, hard plastics, and most other rigid materials. One of the most common questions about CNC drilling concerns its workflow. Below are the steps involved in the CNC drilling process at JUNYU:

- The workpiece is fixed onto the CNC machine table, ensuring its correct positioning. Based on the required hole specifications and materials, the appropriate drill bit and cutting tools are selected.

- The drilling path is generated through CAD/CAM software, and the program is input into the CNC machine. This program includes details such as the position, size, and depth of the hole.

- The CNC machine automatically adjusts the position according to the program, accurately aligning the cutting tool with the center of the hole. The cutting tool begins to rotate and drills the predetermined hole according to the set depth and feed rate.

- The parts are then processed according to any additional requirements or needs from the customer.

- Once the parts are completed, they are packaged and delivered to the customer’s designated location.

Why Choose JUNYU for CNc Drilling?

Rapid Turnaround:With the latest CNC machines, JUNYU can deliver high-precision, fast-turned parts within 10 days.

Precision:Offers high-precision tolerances of ±0.01 mm to ±0.005 mm, customized according to customer specifications.

Expandability:CNC machining is ideal for producing quantities ranging from single pieces to large batches (1 to 10,000 parts).

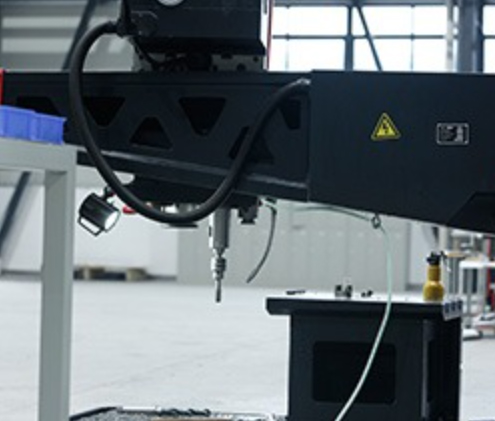

Our CNC Drilling Machine

Precision and productivity are crucial for most industries. With the widespread application of Computer Numerical Control (CNC) technology in metal drilling, JUNYU is able to achieve precise control when setting the diameter, length, and other shapes for drilling, providing standardized components to ensure the safety, performance, and reliability of products or equipment for all users.

Our facilities are each featured, but share the following components

- Spindle: Holds the collet and drill bits, supporting the rotation during the drilling process. The spindle is typically compatible with different types of CNC machines.

- Table: Provides the working space for the drilling machine and is used to place the material to be processed. It is usually designed with standardization, allowing multiple CNC machines to share the same type of table.

- Column: The structural frame that supports other machine components, commonly shared across different CNC drilling machines.

- Control System: The CNC drilling machine’s control system drives the precise movement of mechanical components. This control system can be shared between different machines for program input and operation control.

- Collet and Tool Holding System: Used to secure drill bits or other tools, the same collet and tool holding system is typically used across various machine models.

- Cooling System: Cools the tools and materials during the drilling process to reduce friction. It is usually designed to be shared by multiple CNC machines.

- Drive System: Controls the movement of the machine’s axes, typically using standardized motors and drive components that can be shared across multiple CNC drilling machines.

Materials for CNC Drilling Parts

CNC Drilling Products

CNC Drilling Advantages

CNC drilling offers the following advantages over traditional drilling techniques:

Higher Precision: CNC drilling can produce holes with extremely tight tolerances, ensuring that the hole dimensions are highly consistent with the original design file.

Broader Versatility: CNC drilling can be applied to a variety of materials, including metals, plastics, and wood. Additionally, the use of multiple drill bits allows for the creation of different types of holes.

Greater Reproducibility: CNC computer-controlled drilling eliminates human error, ensuring consistency throughout a batch and across different batches.

Ability to Process Complex Hole Shapes: CNC drilling can process complex hole shapes that would be difficult to achieve with traditional drilling methods.

Customization: CNC drilling allows for easy adjustments to drilling parameters and designs, making it ideal for high-level customization of specific parts or projects.