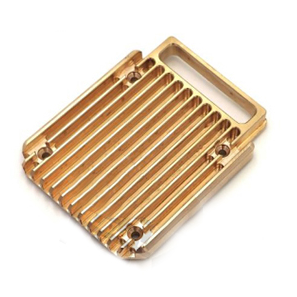

Precision CNC Machining Copper Parts

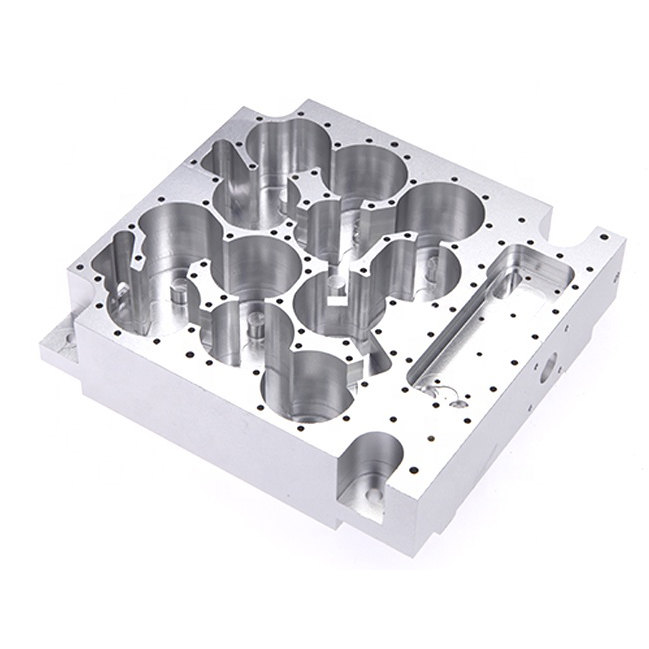

Description Definition of CNC Machining for Copper Components CNC Machining of Copper Parts CNC machining of copper parts refers to the process of precisely shaping copper materials using Computer Numerical Control (CNC) technology. This involves removing material from solid copper or copper alloy workpieces to produce components with accurate geometries and tight tolerances. Due to…